Bioreactor Exporters & Fermenter Exporters — UMA PHARMATECH MACHINERY | Global Industrial Supply

UMA PHARMATECH MACHINERY is a leading global Bioreactor Exporter and Fermenter Exporter delivering high-performance stainless-steel fermenters and bioreactors to industrial customers across the USA, Germany, UK, Australia, South Korea, and India. Our export portfolio spans laboratory benchtop fermenters to pilot and production-scale systems with capacities from a few liters up to tens of thousands of liters. We emphasize quality engineering, international compliance, and turnkey export documentation to simplify customs clearance and installation.

Key strengths:

Full range: lab, pilot, and production fermenters.

Export-ready: CE / ISO-friendly documentation, packing, and freight handling.

Industry focus: pharmaceutical, biotechnology, food & beverage, and chemical processing.

After-sale support: remote commissioning, spare parts, and preventive maintenance.

Whether you need a single production fermenter or a multi-unit pilot line, UMA PHARMATECH MACHINERY combines export experience with robust engineering to deliver reliable, scalable fermentation solutions worldwide.

UMA PHARMATECH MACHINERY: Premier Bioreactor Exporters & Fermenter Exporters for Global Industry

UMA PHARMATECH MACHINERY stands out among Bioreactor Exporters and Fermenter Exporters by combining decades of manufacturing expertise with a global export footprint. Our engineered fermentation systems support R&D, pilot production, and full-scale manufacturing for pharmaceuticals, industrial biotechnology, food & beverage, and specialty chemicals. We export to strategic global markets — including the USA, Germany, UK, Australia, South Korea, and India — with tailored solutions for local compliance and supply-chain realities.

Why Choose UMA PHARMATECH MACHINERY for Exported Bioreactors & Fermenters?

-

Proven reliability: durable stainless-steel construction, hygienic design (3-A/ASME-style practices), and industrial-grade components.

-

Global readiness: we prepare CE-friendly documentation, export packing, and logistics coordination for major ports and airfreight hubs.

-

Application depth: fermentation for antibiotics, enzymes, probiotics, fermented foods, and biochemical production.

-

After-sales care: remote commissioning, spare parts kits, and service contracts for uptime assurance.

Automatic bioreactor manufacturer

Bioreactor with SCADA control

GMP bioreactor manufacturer

Customized industrial bioreactor

Industrial bioreactor with PLC control

Industrial microbial fermenter

Bioreactor manufacturer for probiotics

SS316L industrial bioreactor

Biotech bioreactor system manufacturer

Bioreactor-Manufacturer-Suppliers

Fermenter-Manufacturer-Suppliers

Industrial Fermenter manufacturers

Industrial Bioreactor manufacturers

Export Markets We Serve (Natural integration of top markets)

UMA PHARMATECH MACHINERY ships fermentation systems to high-demand markets such as the USA (biopharma & food-tech hubs), Germany (precision engineering & chemical processing), the UK (contract manufacturing & research), Australia (agri-biotech & food processing), South Korea (advanced biotech manufacturing), and India (scalable production & OEM integrations). Each market receives export documentation and machine configuration aligned with local electrical standards, inlet utilities, and service expectations.

Product Range & Typical Export Capacities

-

Laboratory & Benchtop Bioreactors: 1–50 L — ideal for R&D and scale-up work.

-

Pilot-scale Fermenters: 50–2,000 L — pilot runs, process development, tech transfer.

-

Production-scale Fermenters: 2,000–50,000+ L — commercial fermentation for pharma, enzymes, and food-grade production.

-

Custom Solutions: modular skid-mounted systems, jacketed vessels, CIP/SIP integration, and ATEX-rated options on request.

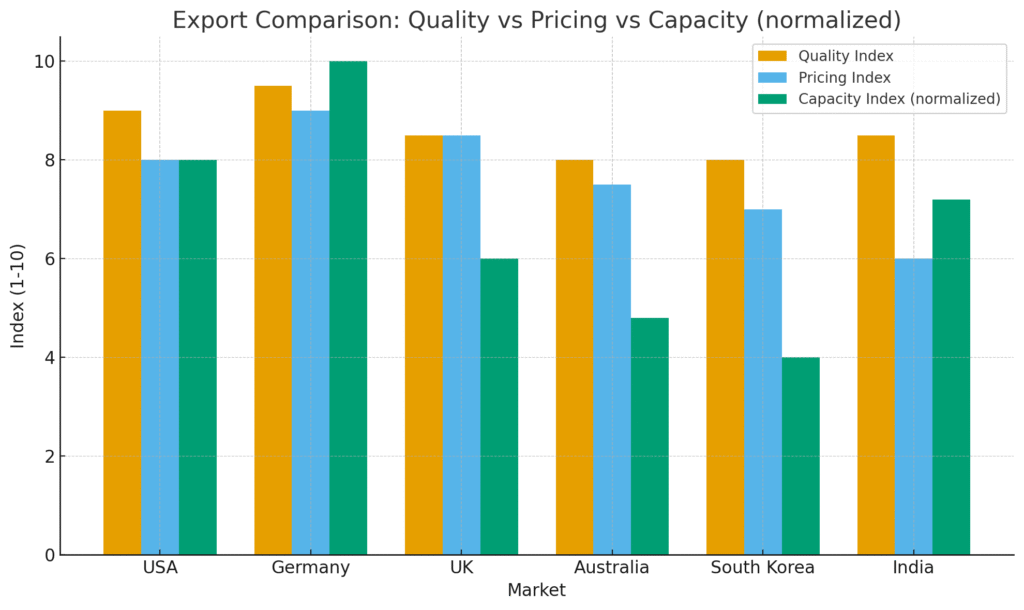

Export Comparison: Quality, Pricing & Capacity (Graph & Table)

Below is a concise table comparing export attributes across major markets to help procurement and procurement managers evaluate fit. (Also shown visually in the export comparison graph above.)

| Market | Typical Quality Index (1–10) | Pricing Index (1–10)* | Typical Max Capacity (L) |

|---|---|---|---|

| USA | 9.0 | 8.0 | 20,000 |

| Germany | 9.5 | 9.0 | 25,000 |

| UK | 8.5 | 8.5 | 15,000 |

| Australia | 8.0 | 7.5 | 12,000 |

| South Korea | 8.0 | 7.0 | 10,000 |

| India | 8.5 | 6.0 | 18,000 |

*Pricing Index is illustrative (higher number = higher typical equipment cost in that market). Use exact quotes for procurement decisions.

Key takeaway: UMA PHARMATECH MACHINERY offers a competitive balance — high build quality and export capability with pricing and capacity options that align to market needs.

Industrial Applications (where exported bioreactors perform best)

-

Pharmaceutical Manufacturing: API fermentation, antibiotic production, fermentation-derived active ingredients.

-

Biotechnology & Research: strain development, enzyme production, and biologics pilot runs.

-

Food & Beverage Processing: probiotics, dairy fermentation, and fermented ingredient production.

-

Chemical & Enzyme Producers: biocatalyst production and fermentation-driven specialty chemicals.

Export Documentation & Support (critical for buying intent)

Purchasing from an exporter requires confidence in documentation and after-sales processes. UMA PHARMATECH MACHINERY provides:

-

Export packing lists, commercial invoices, and origin certificates.

-

FAT (Factory Acceptance Test) reports, wiring diagrams, and PLC/HMI snapshots.

-

Pre-shipment inspection coordination and sea/air freight consolidation.

-

Installation guides, commissioning verification checklists, and operator training (remote or on-site).

These services reduce customs delays and accelerate time-to-production — a major advantage for companies seeking immediate ROI.

Pricing Models & Financing Options

UMA PHARMATECH MACHINERY typically offers:

-

Standard catalog pricing for off-the-shelf lab and benchtop units.

-

Turnkey pricing for fully integrated pilot and production systems (includes skid, piping, and control).

-

Custom quotes for specialized features (ATEX, high-pressure, pharmaceutical-grade finishes).

-

Payment terms: LC, TT, or negotiated milestones for large projects.

Contact our export sales team for a tailored quotation and estimated CIF/FOB pricing. See internal links: Products & Specs | Request a Quote.

Packing, Shipping & Global Logistics

-

Export-grade crating and shock testing for sea transit.

-

Desiccants and anti-corrosion treatments for long transits.

-

Full crate/ISPM-15 wooden packing when required by destination.

-

Coordination of customs clearance documentation and local agent support.

UMA PHARMATECH MACHINERY coordinates end-to-end logistics to lower transit risk and ensure safe delivery.

Table: Quick Specs Snapshot (anchor: #products)

| Product Category | Capacity Range | Typical Lead Time | Key Features |

|---|---|---|---|

| Lab Bioreactor | 1–50 L | 2–4 weeks | Benchtop, PID control, sampling ports |

| Pilot Fermenter | 50–2,000 L | 6–10 weeks | Jacketed, CIP/SIP, scalable control |

| Production Fermenter | 2,000–50,000 L | 10–20+ weeks | Full skid, automation, steam sterilizable |

| Custom Skid Systems | Variable | Quotation-based | Integration, VFDs, PLC, instrumentation |

FAQs

Q1: Do you export complete turnkey fermentation lines including controls and utilities?

A: Yes. UMA PHARMATECH MACHINERY supplies turnkey lines including PLC/HMI integration, piping, pumps, valves, and utility interfaces. We also provide FAT documentation and remote commissioning support.

Q2: What certifications and documentation do you provide for export to the EU or US?

A: We provide material certificates, FAT reports, wiring diagrams, calibration certificates, and CE-friendly documentation. For pharma clients we support GMP-related documentation requirements; please specify during RFQ.

Q3: Can you ship to multiple global hubs and handle customs for large orders?

A: Yes — we coordinate packing, export documentation, and freight forwarding to major ports in the USA, Germany, UK, Australia, South Korea, and India. Local partner support can be arranged for installation and commissioning.

Q4: What are typical lead times for pilot and production fermenters?

A: Pilot-scale systems: typically 6–10 weeks; Production-scale: 10–20+ weeks depending on customization and regulatory needs. Exact lead times are confirmed in the quote.

Q5: Do you offer spare parts and service contracts for exported units?

A: Yes. We offer spare parts kits, preventive maintenance contracts, and remote support packages to reduce downtime and keep operations running.

Strengthening Your Procurement: Internal Anchor Links

-

Jump to product details: Products & Specs

-

For custom inquiries and quotes: Request a Quote

-

Read about shipping & export documentation: Logistics & Export Support

-

FAQs: Export Buyer FAQs

Global Reach + Reliable Performance

As experienced Bioreactor Exporters and Fermenter Exporters, UMA PHARMATECH MACHINERY combines industrial-grade engineering with export-grade logistics and documentation. Whether you operate in the USA, Germany, UK, Australia, South Korea, or India, our teams deliver machines configured for local standards, shipped safely, and supported during installation and operation. For buying managers and engineers focused on uptime, consistent quality, and clear export procedures, UMA PHARMATECH MACHINERY is a partner that aligns manufacturing capability with global distribution.

Connect Here With Us

Ready to buy or request a quote?

-

View product specifications and datasheets: Products & Specs

-

Get a custom quote and export pricing: Request a Quote / Contact

-

Need expedited export support? Email info@umapharmatechmachinery.com or call our export desk: +91-9726923885