Fermenter Manufacturer in Pune | SS Fermenter Bioreactor

For Fermenter Manufacturer in Pune Where Uma Pharmatech Machinery Is Trusted Manufacturer of Insitu Stainless Steel Fermenter Manufacturer in Pune. We Are Supplying Low Cost Fermenter With Inbuilt Heating System at Reasonable Fermenter Prize in India-Maharastra-pune.

Looking for a trusted Fermenter Manufacturer in Pune? Your search ends at Uma Pharmatech Machinery! 🌐 We excel in crafting cutting-edge fermenters, seamlessly combining precision and innovation. Our state-of-the-art Steam Sterilizer Machines ensure optimal performance in diverse applications.

Collaborate with us and witness excellence as we lead the industry in manufacturing Vertical Fermenters in Pune. Explore our expertise in action: YouTube Video.

Discover more about our offerings:

Elevate your fermentation processes with Uma Pharmatech Machinery—your trusted partner in Pune, one of India’s dynamic cities! 🌟

Explore our presence:

Fermenter Manufacturers in Mumbai

Mumbai, the financial capital of India, stands tall as a thriving industrial powerhouse, particularly renowned for its flourishing fermenter and bioreactor manufacturing sector. This article sheds light on Mumbai’s compelling attributes, ranging from its strategic location and well-developed infrastructure to its skilled workforce, making it an irresistible destination for businesses operating in the biotechnology and pharmaceutical domains. Furthermore, Mumbai’s robust manufacturing ecosystem supports the production of top-notch fermenters and bioreactors, bolstered by a wide array of suppliers and specialized service providers. With a vibrant business environment and a vast network of research institutions, the city fosters innovation and collaboration, solidifying its position as a favored choice for manufacturers.

Mumbai’s desirable status as an industrial center is greatly influenced by its advantageous geographic position. Located on India’s western coast, it has simple access to the country’s key domestic and international markets and great connectivity. The city’s well-established transportation system, which includes air, road, and rail modes of transportation, makes it simple to move goods and raw materials, enabling flawless supply chain management for producers of fermenters and bioreactors.

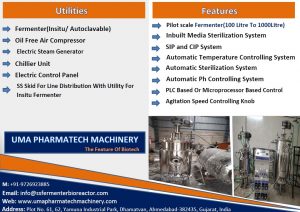

As a top producer of fermenters and bioreactors, we recognize the value of creating high-quality goods that satisfy the demands of our clients. Our selection of fermenters and bioreactors is made to offer the ideal solution for a variety of applications, including the manufacture of biofertilizers, enzymes, APIs, probiotics, vaccines, and vitamins. We will provide you an overview of our goods, their features, and how they might aid you in achieving your manufacturing objectives in this post.

Pilot Scale Fermenter Manufacturer in Pune

Looking for a trusted Fermenter Manufacturer in Pune? Your search ends at Uma Pharmatech Machinery! 🌐 We excel in crafting cutting-edge fermenters, seamlessly combining precision and innovation. Our state-of-the-art Steam Sterilizer Machines ensure optimal performance in diverse applications.

Collaborate with us and witness excellence as we lead the industry in manufacturing Vertical Fermenters in Pune. Explore our expertise in action: YouTube Video.

Discover more about our offerings:

Elevate your fermentation processes with Uma Pharmatech Machinery—your trusted partner in Pune, one of India’s dynamic cities! 🌟

Explore our presence:

Manufacturers of Bioreactors in Pune

Fermenters and bioreactors are critical pieces of equipment for mass production of enzymes and APIs. The increased focus on the healthcare, agriculture, and biotechnology sectors has resulted in a rapid increase in demand for enzymes and APIs in India. This article will go through fermenters and bioreactors for enzyme and API production, as well as the leading vendors of enzyme and API manufacturing plants in India.

Batch Bioreactor Manufacturers in Maharashtra

End uses of fermentation technology are Important. Uma Pharmatech Machinery create to the Research laboratories, Research institution and industrial fermentation plant setup that require Industrial fermentation Skil and experience by providing Best Fermentor Manufacturer in pune-maharastra. Using Our experience we Manufacture and supply and export upstream Process and downstream Process of the Microbiology Heart of the process, these fermentor and bioreactor form the Core of a full integrated bioprocess and Bio Engineering.

Fermenter For Biofertilizer Production in Pune-Maharashtra

Our fermenter for biofertilizer production is designed to provide an efficient and cost-effective solution for the production of high-quality biofertilizers. The fermenter is made from high-quality stainless steel and is equipped with a range of features that make it easy to use and maintain. Some of the key features of our fermenter for biofertilizer production include:

- Large capacity: Our fermenter is available in a range of sizes to meet the needs of different production volumes.

- Efficient mixing: The fermenter is equipped with an efficient mixing system that ensures uniform distribution of nutrients and bacteria.

- Automated control system: Our fermenter is equipped with an advanced control system that allows you to monitor and control the fermentation process with ease.

- Easy to clean: The fermenter is designed for easy cleaning, which ensures that it remains hygienic and free from contamination.

Looking for a reliable Pilot Scale Bioreactor Manufacturer in Pune? Look no further than Uma Pharmatech Machinery! 🌐 We specialize in crafting cutting-edge pilot scale bioreactors, marked by precision and innovation. Our advanced Steam Sterilizer Machines ensure optimal performance in bioprocessing.

Collaborate with us to experience excellence as we lead the industry in manufacturing Vertical Pilot Scale Bioreactors in Pune. Witness our expertise in action: YouTube Video.

Explore our offerings:

- Pilot Scale Bioreactor Suppliers in Pune

- Bioreactor Manufacturer Pune

- Pilot Scale Bioreactor Machine Manufacturer in Pune

Elevate your bioprocessing capabilities with Uma Pharmatech Machinery—your trusted partner in Pune, a city renowned for its industrial prominence! 🌟

What is Industrial Scale Fermenter?

Bioreactor for Enzymes Manufacturing in Maharashtra-Pune

A bioreactor is a specialized type of fermenter that is used for the manufacturing of enzymes on a large scale. Bioreactors are designed to provide optimal conditions for the growth and metabolism of microorganisms, and they are equipped with various sensors and controllers that allow for precise monitoring and control of the process.

A bioreactor for enzyme production must have agitation, aeration, temperature control, pH control, dissolved oxygen control, and foam management. These characteristics ensure that the microorganisms’ growth and metabolism are optimised for enzyme synthesis. Agitation and aeration guarantee that bacteria get enough nutrients and oxygen to grow and thrive. Temperature control guarantees that the temperature of the bioreactor remains at an ideal level for microorganism growth and enzyme production. pH control, dissolved oxygen control, and foam control guarantee that the pH, dissolved oxygen concentration, and foam formation are kept at values suitable for microorganism growth and enzyme production.

Stirred Tank Fermenter Manufacturers in Maharashtra

Uma pharmatech Machinery deal in This Three Category scale for bioreactor manufacturer in pune-maharastra

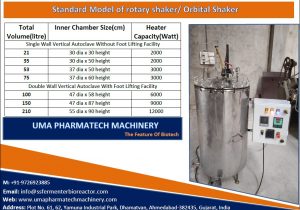

• Laboratory bioreactor and fermenter from 1 Ltr To 25 Ltr

• industrial bioreactor and fermenter from 50 Ltr To 2000 Ltr

• Production scale bioreactor and fermenter from 2kl To 30kl fermentation plant setup

We are Dealing In Maharashtra Main Agriculture and Biofertilizer and Biopesticides Manufacturer in Maharashtra state like:. –

Pune, Nagpur, jalgoan, nanded, Aurangabad, Mumbai, Vasai, Nashik, Dhule, Nagpur, Ahmednagar, Solapur, Panvel, Satara, Boisar, Ratnagiri, Kolhapur, Barshi, Sangli, Latur, Jamkhed, Bhusawal, Lonar, Karanja, Navi Mumbai, Amravati, Akola, Shegaon, Thane, Kopargaon.

Fermenters and bioreactors are IMP equipment for producing enzymes and APIs, which are essential components in many industries. India has a strong presence in the enzyme and API production sectors, with various companies offering a variety of products and services to fulfil their clients’ demands. These companies are well-positioned to address the growing demand for bioprocess by harnessing cutting-edge technologies and process advancements.

What is The Price Of Fermentor and Bioreactor?

Suppliers of Fermenter in Pune

Uma Pharmatech Machinery is involve in manufacturing of industrial fermenter and bioreactor as a Indian Exporter and Indian Supplier. We are Registered Indian Exporter For Pilot Scale Fermenter in India. We Supply In Gujarat, Maharashtra, Karnataka, Tamilnadu, Telangana, Kerala, Punjab, Haryana, West Bengal, Rajasthan, Madhya Pradesh, Assam, Chhattisgarh, Andhra Pradesh, Manipur, Jharkhand, Odisha etc For For Industrial Fermenter as a Manufacturer and Indian Exporter.

What are Bio-reactors and Fermenters?

In the bioprocess industry, bioreactors and fermenters are critical components. They are containers for cultivating and growing microorganisms such as bacteria, yeast, and fungi. Bio-reactors and fermenters provide a controlled environment for the growth of these microorganisms and enable the production of a variety of bioproducts such as enzymes, vaccines, and therapeutic proteins.

Uma Pharmatech Machinery Is Leading Industrial and Laboratory Fermenter and Bioreactor Manufacturer. UPM Is Registered Indian Exporter Of Lab Bioreactor System

We provide a variety of bioreactors and fermenters to meet the specific requirements of your bioprocess. Here are some examples of the equipment we provide:

Stirred Tank Bioreactors: The most common type of bioreactor, they are used for a variety of applications such as cell culture, fermentation, and protein production.

Wave Bioreactors: These are a newer type of bioreactor that creates waves in the culture medium by rocking. They are especially suitable for large-scale production and can be used to create vaccines, therapeutic proteins, and other bioproducts.

Photobioreactors are specialized bioreactors that use light to grow microorganisms like algae. They are widely used in the production of biofuels and other forms of renewable energy.

Production fermenter Features For Biofertilizer and Enzymes Production

Uma Pharmatech Machinery Offerings-

• Bio-Reactors And Fermenters

• Bio – Waste Decontamination Systems / Sterilization Systems /

Inactivation Systems

• PWDS, WFIDS, CSDS Systems

• CIP Plants

• Pharmaceutical Machinery and Bio-pharma Custom Built

Modules

• Mixing And Blending Vessels

• Dairy/Starch Projects

• Drying And Evaporation Projects

• Biorefineries

• Piping Engineering

• Plug-in Temperature / Brix / pH / Pressure/ Flow Control Modules

• Electrical And Automation Engineering

• Flow Control Equipment

• All Types Of Valves And Valve Automation

Boreactor for vaccine production in India

We are ‘Professionals in Process/ Product Technologies’ with following

expertise-

• Conceptualization and Engineering of Projects

• Module and skid building

• Custom-built solutions

• Innovative hygiene Products for Pharma/ Dairy Industry

• Expertise in Pharma, Food, Natural resource based projects

• Business partners of world class products from Europe and USA.

Fermenter For Vitamins Production in India

Our fermenter for vitamins production is designed to provide an efficient and cost-effective solution for the production of high-quality vitamins. The fermenter is made from high-quality stainless steel and is equipped with a range of features that make it easy to use and maintain. Some of the key features of our fermenter for vitamins production include:

- Optimal environment: Our fermenter provides an optimal environment for the growth and production of vitamins, which ensures high yields and consistent quality.

- Automated control system: Our fermenter is equipped with an advanced control system that allows you to monitor and control the fermentation process with ease, ensuring the quality of the final product.

- Easy to scale up: Our fermenter is designed to be easily scalable, which makes it ideal for both small and large-scale production.

- Easy to clean: The fermenter is designed for easy cleaning, which ensures that it remains hygienic and free from contamination, ensuring the purity of the final product.

What is Industrial Scale Fermenter?

Fermenters and bioreactor Volume Higher then 10000Litter is covered in Industrial Bioreactor. Uma pharma tech Machinery is One Of The Trusted Manufacturer Of Fermenter and Bioreactor From India. Industrial Bioreactor Cost Start From 40 Lac In UPM-Ahmedabad Gujarat india.

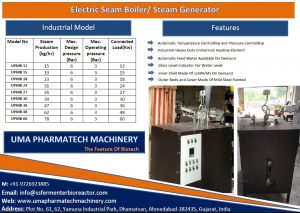

Cost Of 1000L Fermenter Made Of Uma Pharmatech Machinery is Start From 8Lac In Ahmedabad Gujarat. Total Cost Of Fermenter Plant With Utility is Rs 38Lac/ Set. UPM Made Fermenter Comes With Utility Like Chiller, Oil Free Air Compressor, Steam Boiler, SS Skid and Pipeline, Control Panel, Ph Measurement and Control. Temperature and Pressure Control

Enzyme Production Fermenter In Pune-Maharashtra

A fermenter is a big jar in which microorganisms such as bacteria and fungi are grown in order to create enzymes. Enzyme synthesis is accomplished by the employment of particular microbes capable of creating vast numbers of enzymes. Fermenters are designed to provide optimal conditions for microbial growth and reproduction.

Temperature control, pH control, agitation, and aeration are all important elements of a fermenter for enzyme production. These characteristics are critical for microbial growth and metabolism, as well as enzyme synthesis. Temperature control guarantees that the fermenter’s temperature remains at an ideal level for the growth of microorganisms. pH management guarantees that the pH of the fermenter remains at a level appropriate for microbial growth and enzyme synthesis. Agitation and aeration ensure that bacteria are equally distributed throughout the fermenter and that they have enough nutrients and oxygen to grow and metabolise.

As a leading manufacturer of fermenters and bioreactors, we are committed to providing high-quality products that meet the needs of our customers. Our range of fermenters and bioreactors for biofertilizer production, enzymes production, API production,

Contact US

- 61, Yamuna Industrial Park, Opp. Sardar Patel Estale, Vanch-dhamatvan Road, Dhamatvan, Ahmedabad, Gijarat, India-382435

- +91-9726923885, +91-8866137364

- [email protected]

- [email protected]

- [email protected]

Quick Links