Ribbon Blender Manufacturer in maharastra

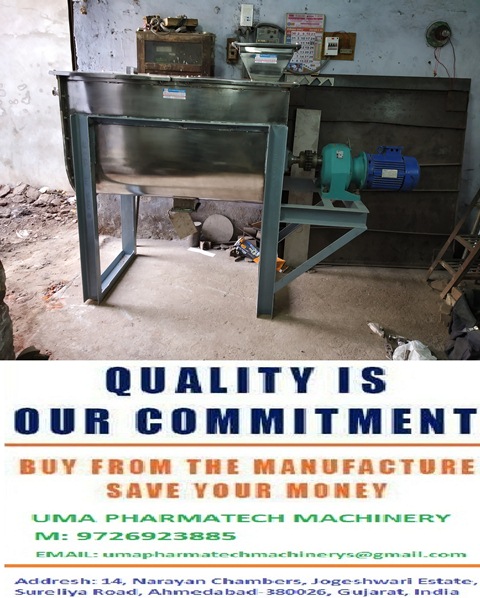

We Manufacturer Industrial Ribbon Blender Mixer in Maharashtra. We Have Inhouse Manufacturing For Up to 5 Ton For Ribbon Blender Manufacturing. We Located In Ahmedabad and Supply in Maharashtra.

Do you need a dependable and high-quality ribbon blender manufacturer in Maharashtra, India? Look no further than our company, which has been serving customers for years with top-notch blending solutions. Our ribbon blenders are designed with precision and care, providing efficient and effective mixing of powders, granules, and other materials.

In this comprehensive guide, we will take a deep dive into the world of ribbon blenders, discussing everything from their benefits to their construction, and how to choose the right blender for your specific needs. Let’s get started!

What is a Ribbon Blender?

Construction of a Ribbon Blender

Ribbon blenders are normally made of high-quality stainless steel, ensuring their durability and lifespan. The ribbon agitator is usually constructed of a high-strength steel alloy, such as carbon steel or stainless steel.

The U-shaped trough is designed for easy material loading and unloading, with a choice of discharge options such as sliding gates, butterfly valves, and more. The trough can also be insulated to avoid heat loss or to keep a certain temperature while mixing.

Custom Designed Solutions

We recognise that each client has specific wants and requirements. As a result, we provide custom-designed Ribbon Blenders that are adapted to your individual needs.

Our experts will collaborate with you to understand your requirements and present you with a solution that fits your requirements. We will collaborate with you from the original design phase through the final product to ensure that the end result fulfils your expectations.

Our Custom Designed Solutions include:

Custom Blade Design: We can create custom blades to fit your exact mixing requirements.

Variable Speed Drive: Our blenders are available with variable speed drives, which provide you more control over the mixing process.

Material Options: For the construction of our Ribbon Blenders, we provide a variety of materials such as stainless steel, mild steel, and other alloys.

Quality Assurance

Our organisation is dedicated to offering the finest quality products and services to our clients. To ensure that every product we make meets our high standards, we have a thorough quality control process in place.

Our Quality Control Process consists of the following steps:

All inbound materials and components are inspected to verify they fit our standards.

Inspections are performed on a regular basis during the manufacturing process to guarantee that all goods satisfy our criteria.

Final product inspection and testing before shipping to our clients.

Industries and lab that use Ribbon Blender:

Uma Pharmatech Machinery have been Ribbon Blender Manufacturers that are used in various industries including Pharmaceutical, chemicals, food and cosmetic.

UPM hold expertise in offering a wide range of Roasting Machine. These are admired for application specific design, robustness and consistent performance. These are engineered using easy maintenance, fines finish and high production rate. Following the precise demands of our clients, we provide these in various range and models.

Advance Features

Longer service life

Easy maintenance

Abrasion resistant

we are manufacturer of ribbon Blender for spice mixing.

Ribbon Mixer is operated smoothly without pollution and noice, Applied to mix different dry powder and granules material uniformly. This machine having fast mixing speed and good mixing effect.

Special Application

Ribbon Mixer is suitable for various material mixing, which is widely applied in food product and Spices & Ayurvedic & Herbal Powder & daily use chemical & Colors & organic & inorganic matter & Dyestuff, Pesticide & Fertilizers & and other more industry.

With the Use of our advanced Facilities and quality raw material- we are able to Manufacturing Extreme quality industrial Ribbon Powder Mixer. Ribbon Blender Powder Mixer finds its application in several manufacturing industries and lab. For the Use of mixing and continous blending of Many dry powder and wet Liquid. Uma Pharmatech Machinery provide this product in the market in Huge Size model and at a Resonable cost, which is quite reasonable.

Special Features:

Contact parts made of SS 316/ SS304 as per customer requirement.

Double Helical agitator with Continous speed for uniform dry mix and perfect wet mix all batch.

The general structure Ribbon Blender has non-contact parts made of Mild Steeel Or CS as Per customer requirement.

The GMP Machine non-contact parts are made of SS304/316.

The contact parts of the blender have a mirror and matt finish.

All the non-contact components are polished in matt 220 grit and mirror finished in GMP Model.

In GMP model, all the safety guards and covers are made of Stainless steel 304

Special Features:-

You can choose to get the parts of your blender designed with SS 316

Uma Pharmatech Machinery can customize a variable speed drive or a double speed stirrer as per your Requirements.

Being finest Ribbon Blender Manufacturer in maharastra and Gujarat.

UPM Manufacture flameproof/ FLP/ NFLP models on special customer demand.

Industry which use of Ribbon Blender:-

Uma Pharmatech Machinery have been Ribbon Blender Manufacturer Which are used in various industry including Pharma, chemical & food and cosmetic.

Owing to its high quality & reasonable Cost, Our ribbon mixer manufactured by UPM is highly Competitive for in the market. OUR ribbon mixer is used for the purpose of blending several powders and Liquid culture, in several industry. The production process of Our Ribbon blender involves use of quality raw materials Or advanced machinery & send this product through a number of quality check for the purpose of quality maintain assurance throught all batch.

Advanages of Double Helical Mixing Ribbon Blender:-

Blender Contact parts made of customer requirement.

Double/ single Helical agitator with single speed for uniform dry mix and perfect wet mix in all batch.

The Regular structure Ribbon Blender has non-contact parts made of customer requirement.

The GMP/NGMP Machine non-contact parts are made of SS304

The contact parts of the blender have a Matt finish

All the non-contact parts are polished in matt finished in GMP/NGMP Ribbon Blenders.

In GMP model, all the safety guards and covers are made of SS304

Extreame Demandable Features:-

You can choose to get the parts of your blender designed with SS316

We can customize a variable speed drive or a double speed stirrer as per your Requirements.

Being TOP 10 Ribbon Blender Manufacturer in maharastra and gujarat, UPM Manufacture flame proof and NFLP model on special customer demand.

Choosing the Right Ribbon Blender

Choosing the best ribbon blender for your needs necessitates careful consideration of numerous important elements. Among the most crucial aspects to consider are:

Material Characteristics: The sort of material you will be combining will influence the size and design of the ribbon blender you require. Different mixing settings will be required for materials with varying densities, particle sizes, and flow qualities.

The capacity of the ribbon blender you need will be determined by the amount of material you need to combine at one time. It is Important to select a blender that is large enough to meet your demands without being overly huge, as this can lead to poor blending and wasted space.

The speed of the ribbon agitator will affect the mixing efficiency and final blend quality. It is critical to select a blender with a speed adequate for the components being combined.

The ribbon blender’s construction is also an important factor to consider. Look for a blender that is made of high-quality components and has a long-lasting and dependable design.

Why Choose Our Ribbon Blenders?

Contact US

- 61, Yamuna Industrial Park, Opp. Sardar Patel Estale, Vanch-dhamatvan Road, Dhamatvan, Ahmedabad, Gijarat, India-382435

- +91-9726923885, +91-8866137364

- [email protected]

- [email protected]

- [email protected]