Autoclavable Glass Fermenter manufacturer For Laboratory

Autoclavable Glass and insitu ss Fermenter and bioreactor manufacturer For Laboratory uma pharmatech machinery is well known name. UPM Developed Special Designed Lab Scale Autoclavable Glass Fermenter for research institute and training to students.

UPM insitu ss Fermenter Pressurized Condition Can Not Be Achieve Due To Glass Body.

In This Model For Sterilization of Media Not Require any Heat Source Like Steam Generator. This Model Can Be Autoclave After Removing clamps Of Motor.

Glass Fermenter is an important piece of equipment used in the fermentation process in the biotechnology industry. Fermentation is used to make a variety of industrial and pharmaceutical products, such as vaccines, enzymes, and antibiotics. A glass fermenter is a vessel used under controlled conditions to grow and maintain a specific population of microorganisms. Glass fermenter manufacturers are critical in providing high-quality fermenters to biotech companies. This article will go over the benefits of glass fermenters, different types of glass fermenters, factors to consider when selecting a glass fermenter manufacturer, top glass fermenter manufacturers, tips for selecting the right glass fermenter, and frequently asked questions.

Suppliers of API Manufacturing Plants in India:

India is a significant API supplier to the global pharmaceutical industry. The country is home to a huge number of API manufacturing plants that manufacture a diverse range of substances, from simple generics to complicated biologics.

Dr. Reddy’s Laboratories, Sun Pharmaceutical Industries, and Lupin Limited are among the leading participants in the Indian API sector. These firms have vast experience in API manufacturing and are known for producing high-quality products while adhering to worldwide regulatory norms.

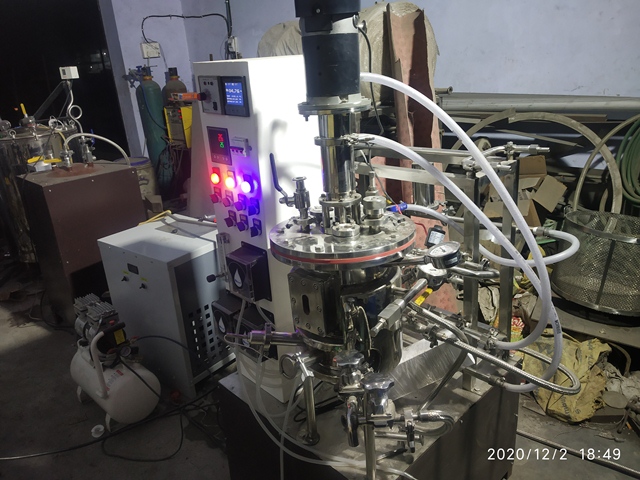

Insitu stainless steel bioreactor Fermentor

UPM fermenter is very east To operate and control with electronic easy programmable plc controlling system. UPM is provide Fully Automatic , Semi Automatic and Automatic and manual fermenter for various application and customer requirement.

UPM have inhouse manufacturing set up for design of fermenter, manufacturing of fermenter up to 30000Litter fermenter. Autoclavable glass bioreactor used for pharmaceutical and chemical industries in India.

Improved Productivity and Yield

One of the most significant advantages of bioreactors and fermenters is that they can significantly improve productivity and yield. The controlled conditions inside these vessels, including temperature, pH, oxygen supply, and nutrient availability, ensure that cells or microorganisms grow and reproduce at their optimal rates. As a result, the production of enzymes, biofertilizers, and other substances can be optimized, leading to higher yields and better productivity.

Reduced Production Costs

Bioreactors and fermenters can also help reduce production costs. These tools can produce large quantities of substances using a small amount of raw material and energy. The controlled conditions inside these vessels can also minimize wastage, leading to lower production costs. Moreover, the ability to optimize production can lead to more efficient use of resources, further reducing costs.

This Model Of insitu ss Fermenter of ump manufacturer Generally Used For R&D Purpose and in College. this model available for small scale capacity up to 20Litter.

Standard Model

- 5Litter insitu stainless steel Bioreactor Fermenter

- 10Litter insitu stainless steel Bioreactor Fermenter

Types of Bioreactors and Fermenters

There are several types of bioreactors and fermenters available on the market. The type of bioreactor or fermenter used for a particular application depends on several factors, including the type of cells or microorganisms being grown, the scale of production, and the desired end-product. Here are some of the most common types of bioreactors and fermenters:

Stirred-Tank Bioreactors

Stirred-tank bioreactors, also known as STRs or simply bioreactors, are the most common type of bioreactor used for industrial production. These vessels consist of a cylindrical tank with a stirring mechanism that keeps the cells or microorganisms in suspension and ensures proper mixing. STRs can be designed for various volumes, ranging from a few liters to several thousand liters.

Air-Lift Bioreactors

Air-lift bioreactors are similar to stirred-tank bioreactors but use air bubbles instead of a mechanical stirrer to mix the cells or microorganisms. These bioreactors are particularly useful for growing fragile cells or microorganisms that can be damaged by mechanical agitation.

Packed-Bed Bioreactors

Packed-bed bioreactors use a bed of solid material, such as plastic beads or glass beads, to support the cells or microorganisms. The cells or microorganisms grow on the surface of the beads and are supplied with nutrients and oxygen through the interstitial spaces between the beads. Packed-bed bioreactors are particularly useful for growing cells or microorganisms that require a large surface area for attachment.

Automatic Control Industrial Fermenter

Uma Pharmatech Machinery’s legacy stretches far beyond the bustling streets of Surat. As an industrial fermenter manufacturer in India, their influence resonates throughout the nation’s industrial heartlands. From the pharmaceutical hubs to the burgeoning biotech clusters, their fermenters become catalysts for progress, fostering a culture of self-reliance and technological evolution.

Cost of Fermenter For Industrial 1000L-100L

Considering the cost of fermenters goes beyond financial considerations. It’s an investment in progress, innovation, and industrial advancement. Uma Pharmatech Machinery understands this profound impact, offering fermenters that embody not only engineering excellence but also the potential for transformative change across sectors.

Download Quotation Of Industrial Fermenter

Automatic Control Laboratory Bioreactor

The producers of laboratory fermenters are a significant force in India’s scientific and industrial scene. They are experts in creating state-of-the-art fermentation machinery, promoting progress in biotechnology, pharmaceuticals, and research. To advance India’s advancement in a variety of scientific fields, these manufacturers demonstrate knowledge, ensuring quality, innovation, and effective solutions.

Download Quotation of Lab Fermenter

Specification of Insitu SS Fermenter For Laboratory

· 10 Litter SS Fermenter · Pt-100 Temperature Sensor and Digital Temperature Measurement System · Mini Oil Free Air Compressor(1 Hp) Suitable For 10 Litter Fermenter · Air Flow Control Through Rota meter · Electromagnetic Agitator Speed Control Knob (RPM Controller) with control panel · Electric Steam Generator (All Ms Body-50Litter Tank with Water Level Tube)(Manual Feed Water-6kw)

| 1 Nos | info@umapharmatechmachinery.com |

Automatic Ph. Measurement & Control System | 1 Nos | Extra Cost On Request |

Do Sensor(Indian Made) | 1 Nos | Extra Cost On Request |

10L SS Fermenter With Oil Free Air Compressor and Electric Steam Boiler unit

Agitation Stirring Arrangement

Top Mounted Agitator Shaft With Lab Seal and 2 Nos Adjustable Ruston Turbine

- PMDC Motor(RPM 1200)

- DC/Ac Drive For Agitator Speed Controller Knob

Aeration Control System

- Air Flow Rota meter With Manual Flow Control Valve

Pressure Control System

- Pressure Regulator For Process Pressure Control

Digital Temperature Measurement System

- Pt -100 Temperature Sensor For Accurate Temperature Measurement

- Digital Temperature Indicator

Control Panel

- Powder Coated Control Panel With Various Panel Mounted Accessories, Instruments and Controller

Fermenter Construction and Specification

Total Volune:10 Litter

Working Volume:70% Of Total Volume

L/d Ratio : 1: 1.5 to 2.5

Contact Part: SS 316L

Non Contact Parts: SS 304

Contact Part: SS 316L

Outer Finish : Matt Finished

Inner Finish : 220 Grit Finish

Motor : PMDC

Max. Output RPM Speed : 1200

Speed Controlling: Using Micro controller

Temperature Sensor : PT-100 Type(Sterilizable)

Temperature Controlling System : PID Control Digital Display

Air Inlet Filter : 0.2 Micron PP Filter

Air Outlet Filter : 0.2 Micron PP Filter

Air Outlet : Through Shell Tube Type Condenser ( Heat Exchanger)

Spurger System : Ring Type Air Spurger System At Bottom

Mechanical Seal : For Zero Contamination and Reduce Air Leakage

Baffle : 4 Nos( Size Vessel Dia/10)

Adjustable Impeller : 2 Nos Of Adjustable Ruston Turbine( Six Blade)(Vessel Dia/3)

Automatic Control Pilot Scale Fermenter

In India, pilot scale fermenter manufacturers are vital catalysts for innovation. They produce advanced fermentation systems, crucial for scaling up biotechnological processes. These manufacturers drive research, bridging the gap between lab experiments and large-scale production, bolstering sectors like pharmaceuticals and biofuels, and contributing significantly to India’s scientific and economic growth.

Specification of Pilot Scale Fermenter

Download Pilot Cale Fermenter Prize List

Advantages of Glass Fermenter

Non-reactive nature of glass Transparency and monitoring

Sterilization

Economical

Durable

Types of Glass Fermenter

Batch Fermenter Continuous Fermenter

Anaerobic Fermenter

Aerobic Fermenter

Factors to Consider When Choosing a Glass Fermenter Manufacturer

Quality of Glass

Design and Engineering

Service and Support

Price of fermenter and bioreactor

Top Glass Fermenter Manufacturers

Maruti Engineering Works

Uma Pharmatech Machinery

ssfermenterbioreactor.com

UPM

Tejas Pharma Equipment

Uma Pharma

Fermenters for the Production of Biofertilizers

A fermenter is a device that aids the fermentation process by creating an optimum environment for microbial development. Fermenters come in a variety of sizes and forms, and can be customized to meet the specific needs of the biofertilizer manufacturing process. Batch fermenters and continuous fermenters are the two most frequent types of fermenters used in biofertilizer production.

Batch fermenters are the most basic and cost-effective type of fermenter. A fixed amount of substrate is put into the vessel in batch fermenters, and the fermentation process is repeated until the required level of microbe growth is achieved. When the procedure is finished, the fermented product is harvested and the vessel is emptied and cleaned in preparation for the next batch.

Advanced Features Of UPM Fermenter

Zero contamination free finish product can be achived

Superior functioning Agitator with speed controlling facilities

Ethernet system with PLC Control With 10 inch touch Screen HMI

Ph Controlling System With Peristaltic Pump 2 NOs- and Bottle Attachment With 0.2 Microne Air vent Filter(PTFE)

Agitation, Aeration, Temperature, pH, O2, Total Bio Mass and pCO2, pressure and level as an option

Bioreactors for the Production of Biofertilizer

Upm have Facilities Inhouse Crane 10 ton capacity which is very easy to manufacture without and damage.

Upm have inhouse facilities for finishing of fermenter for attractive quality and performance for mirror pollish.

UPM Have Facilities Electric Panel Manufacturing and Programming As Per Automation Required By Customer.

we have more then 70+ customer All Over The World.

for more detail please Click Here

Enzyme Production Fermenter:

A fermenter is a type of bioreactor specifically built for enzyme production. Enzymes are vital proteins found in a variety of sectors, including food, pharmaceuticals, and textiles. Fermenters are used to grow microorganisms that produce enzymes in high quantities, such as bacteria, yeast, and fungi.

One of the primary advantages of employing a fermenter for enzyme production is that it enables for large-scale enzyme manufacturing. This is significant because enzymes are frequently utilised in huge amounts in industrial processes. Depending on the individual requirements of the enzyme manufacturing process, fermenters can be built to generate enzymes in batch, fed-batch, or continuous modes of operation.

Uma Pharmatech Machinery Manufacturing Unit For Fermenter and Bioreactor Is Located In Ahmedabad , Gujarat, India. We Supply Our Fermentation Plant For API, Antibiotics, Probiotics, Biofertilizer, Biopesticides and Many More. We Supply Our Machinery in Ahmedabad, Vadodara, Rajkot, Surat, Navsari, Vapi, Morbi, Valsad, Bhavnagar, Jamnagar, Nadiad, Bhuj, Bharuch, Ankleshwar, Dahej, Gandhinagar, Ahmedabad, Mehsana, Himmatnagar, and Most City in Gujarat.

It’s important to pick the proper equipment when it comes to industrial operations like fermentation and bioreactor production. Given the abundance of products on the market, this can be a difficult undertaking. We will give you information about the top producers, suppliers, and exporters of industrial fermenters and bioreactors Here.

Manufacturer of Bioreactors and Industrial Fermenters

Your needs-specific equipment of the greatest quality should be available from a reputable manufacturer of Fermenter and Bioreactor. UPM Inc. is one such manufacturer. They have accumulated years of experience in the field and have established a reputation for giving clients high-quality equipment.

They use cutting-edge technology to construct their industrial fermenters and bioreactors, guaranteeing excellent efficiency and ideal performance.

Manufacturer of Pilot Scale Fermenter and Bioreactor

When it comes to pilot scale fermentation and bioreactor manufacturing, it is important to choose a manufacturer that can provide you with high-quality equipment. One such Fermenter manufacturer is Uma Pharmatech Machinery. They have years of experience in the industry and have built a reputation for providing customers with top-quality equipment.

Their pilot scale fermenters and bioreactors are built using the latest technology, ensuring high efficiency and optimal performance. They also offer custom solutions to cater to the specific needs of their clients.

Advantages of Glass Fermenter:

When compared to other materials such as plastic or stainless steel, a glass fermenter is far superior. Here are some of the benefits of using a glass fermenter:

Glass is non-reactive, so it does not react with the substances present in the fermentation process, ensuring the purity of the final product. It is non-toxic, and during the fermentation process, no harmful substances are released.

Transparency and monitoring: Because glass is transparent, visual monitoring of the fermentation process is possible without disturbing the environment. This allows scientists to monitor cell growth, nutrient uptake, and metabolic activity, ensuring optimal microbial growth conditions.

Glass can withstand high temperatures during sterilization processes without being damaged, resulting in a sterile environment. It can be sterilized in several ways, including autoclaving and dry heat sterilization.

Glass fermenters are more cost effective than Steel Body Fermenter because they are more durable and have a longer lifespan. They require little maintenance and do not need to be replaced frequently.

Glass fermenters are extremely durable and resistant to wear and tear, allowing for long-term use. They can withstand high pressure and are resistant to thermal shock, which prevents breakage.

Different Types Of Fermenters

Enzyme Manufacturing Bioreactor:

Bioreactors are another form of vessel that can be utilized for enzyme production. Bioreactors, like fermenters, are intended to develop microorganisms that create enzymes. Bioreactors, on the other hand, can be used to produce additional bioproducts such as antibiotics, vaccines, and biofuels.

Bioreactors can be configured to run in a number of modes, including batch, fed-batch, continuous, and perfusion. They can also be outfitted with a variety of sensors and controls for monitoring and adjusting important process factors like temperature, pH, dissolved oxygen, and nutrient levels.

Industrial and Laboratory Fermenter Bioreactor Manufacturers

- uma Pharmatech Machinery

- July 12, 2025

- bioreactor bioreactor Exporters fermenter bioreactor city and state fermenter Exporters Pilot Scale Bioreactor Pilot Scale fermenter

Pilot Scale Bioreactor Suppliers in Italy | UMA PHARMATECH MACHINERY

- uma Pharmatech Machinery

- July 12, 2025

- bioreactor bioreactor Exporters fermenter bioreactor city and state fermenter Exporters Pilot Scale Bioreactor Pilot Scale fermenter

Pilot Scale Bioreactor Suppliers in France | UMA PHARMATECH MACHINERY

- uma Pharmatech Machinery

- July 12, 2025

- bioreactor bioreactor Exporters fermenter bioreactor city and state fermenter Exporters Pilot Scale Bioreactor Pilot Scale fermenter

Pilot Scale Bioreactor Suppliers in Russia | UMA PHARMATECH MACHINERY

- uma Pharmatech Machinery

- July 12, 2025

- bioreactor bioreactor Exporters fermenter bioreactor city and state fermenter Exporters Pilot Scale Bioreactor Pilot Scale fermenter

Pilot Scale Bioreactor Suppliers in United Kingdom (UK) | UMA PHARMATECH MACHINERY

- uma Pharmatech Machinery

- July 12, 2025

- bioreactor bioreactor Exporters fermenter bioreactor city and state fermenter Exporters Pilot Scale Bioreactor Pilot Scale fermenter

Pilot Scale Bioreactor Suppliers in Germany | UMA PHARMATECH MACHINERY

- uma Pharmatech Machinery

- July 31, 2025

- bioreactor bioreactor Exporters fermenter bioreactor city and state fermenter Exporters Pilot Scale Bioreactor Pilot Scale fermenter

Pilot Scale Bioreactor Suppliers in USA | UMA PHARMATECH MACHINERY

- uma Pharmatech Machinery

- July 31, 2025

- bioreactor bioreactor Exporters fermenter bioreactor city and state fermenter Exporters Pilot Scale Bioreactor Pilot Scale fermenter

Laboratory Bioreactor Suppliers in Finland

- uma Pharmatech Machinery

- July 31, 2025

- bioreactor Exporters fermenter bioreactor city and state fermenter Exporters Laboratory Bioreactor laboratory fermenter

Laboratory Bioreactor Suppliers in Norway

- uma Pharmatech Machinery

- July 31, 2025

- bioreactor Exporters fermenter bioreactor city and state fermenter Exporters Laboratory Bioreactor laboratory fermenter

Laboratory Bioreactor Suppliers in Denmark

- uma Pharmatech Machinery

- July 31, 2025

- bioreactor Exporters fermenter bioreactor city and state fermenter Exporters Laboratory Bioreactor laboratory fermenter

Laboratory Bioreactor Suppliers in Sweden

- uma Pharmatech Machinery

- July 31, 2025

- bioreactor Exporters fermenter bioreactor city and state fermenter Exporters Laboratory Bioreactor laboratory fermenter

Laboratory Bioreactor Suppliers in Switzerland | Uma Pharmatech Machinery

- uma Pharmatech Machinery

- July 31, 2025

- bioreactor Exporters fermenter bioreactor city and state fermenter Exporters Laboratory Bioreactor laboratory fermenter

Laboratory Bioreactor Suppliers in Netherlands | Bench Top & Glass Fermenter – Uma Pharmatech Machinery

- uma Pharmatech Machinery

- July 31, 2025

- bioreactor Exporters fermenter bioreactor city and state fermenter Exporters Laboratory Bioreactor laboratory fermenter

Laboratory Bioreactor Suppliers in Spain | Uma Pharmatech Machinery

- uma Pharmatech Machinery

- July 16, 2025

- bioreactor Exporters fermenter bioreactor city and state fermenter Exporters Laboratory Bioreactor laboratory fermenter

Laboratory Bioreactor Suppliers in France

- uma Pharmatech Machinery

- July 16, 2025

- bioreactor Exporters fermenter bioreactor city and state fermenter Exporters Laboratory Bioreactor laboratory fermenter

Laboratory Bioreactor Suppliers in Italy

- uma Pharmatech Machinery

- July 16, 2025

- bioreactor Exporters fermenter bioreactor city and state fermenter Exporters Laboratory Bioreactor laboratory fermenter

Laboratory Bioreactor Suppliers in Australia

- uma Pharmatech Machinery

- July 16, 2025

- bioreactor Exporters fermenter bioreactor city and state fermenter Exporters Laboratory Bioreactor laboratory fermenter

Laboratory Bioreactor Suppliers in Canada

- uma Pharmatech Machinery

- July 16, 2025

- bioreactor Exporters fermenter bioreactor city and state fermenter Exporters Laboratory Bioreactor laboratory fermenter

Laboratory Bioreactor Suppliers in United Kingdom

- uma Pharmatech Machinery

- July 16, 2025

- bioreactor Exporters fermenter bioreactor city and state fermenter Exporters Laboratory Bioreactor laboratory fermenter

Laboratory Bioreactor Suppliers in United States

- uma Pharmatech Machinery

- July 16, 2025

- bioreactor Exporters fermenter bioreactor city and state fermenter Exporters Laboratory Bioreactor laboratory fermenter

Laboratory Bioreactor Suppliers in Germany

- uma Pharmatech Machinery

- July 16, 2025

- bioreactor Exporters fermenter bioreactor city and state fermenter Exporters Laboratory Bioreactor laboratory fermenter

Pilot Scale Fermenter Manufacturer

- uma Pharmatech Machinery

- July 10, 2025

- bioreactor fermenter

Laboratory Bioreactor Exporter | Buy Advanced Lab Bioreactors – Uma Pharmatech Machinery

- uma Pharmatech Machinery

- July 10, 2025

- bioreactor fermenter

Bioreactor Manufacturer in Kenya | Buy Lab & Industrial Bioreactors

- uma Pharmatech Machinery

- July 10, 2025

- bioreactor fermenter

Industrial Bioreactor Manufacturer | Industrial Fermenter Suppliers and Exporters in India

- uma Pharmatech Machinery

- July 10, 2025

- bioreactor fermenter

Bioreactor Exporters & Fermenter Exporters — UMA PHARMATECH MACHINERY | Global Industrial Supply

- uma Pharmatech Machinery

- July 10, 2025

- bioreactor Exporters fermenter Exporters

Bioreactor Exporters and Fermenter Exporters – Global Supply Solutions

- uma Pharmatech Machinery

- July 10, 2025

- bioreactor Exporters fermenter Exporters

Industrial Fermenter Exporters | Industrial Bioreactor Exporters | Pilot Scale Fermenter Exporters – UMA PHARMATECH MACHINERY

- uma Pharmatech Machinery

- July 10, 2025

- bioreactor Exporters fermenter Exporters

Industrial Fermenter & Bioreactor Exporters | Pilot Scale Fermenter Exporters – UMA Pharmatech Machinery

- uma Pharmatech Machinery

- July 24, 2025

- bioreactor Exporters fermenter Exporters

Automatic Fermenter System

- uma Pharmatech Machinery

- July 10, 2025

- bioreactor Exporters bioreactor suppliers fermenter Exporters fermenter Suppliers

Stainless steel bioreactor manufacturer and exporters

- uma Pharmatech Machinery

- July 10, 2025

- bioreactor Exporters bioreactor suppliers fermenter Exporters fermenter Suppliers

Bioreactor For Probiotics Production

- uma Pharmatech Machinery

- July 25, 2025

- bioreactor fermenter

Bioreactor For API Manufacturing

- uma Pharmatech Machinery

- July 25, 2025

- bioreactor fermenter

Automatic bioreactor manufacturer

- UMA PHARMATECH MACHINERY-UPM

- July 3, 2025

- Industrial Bioreactor Industrial Fermenter

- automatic bioreactor manufacturer, enzyme fermenter with SCADA, industrial bioreactor India, UMA PHARMATECH MACHINERY, bioreactor automation system

Bioreactor with SCADA control

- UMA PHARMATECH MACHINERY-UPM

- July 3, 2025

- Industrial Bioreactor Industrial Fermenter

GMP bioreactor manufacturer

- UMA PHARMATECH MACHINERY-UPM

- July 3, 2025

- Industrial Bioreactor Industrial Fermenter

Customized industrial bioreactor

- UMA PHARMATECH MACHINERY-UPM

- July 5, 2025

- Industrial Bioreactor Industrial Fermenter

Industrial bioreactor with PLC control

- UMA PHARMATECH MACHINERY-UPM

- July 5, 2025

- Industrial Bioreactor Industrial Fermenter

Industrial microbial fermenter

- UMA PHARMATECH MACHINERY-UPM

- July 5, 2025

- Industrial Bioreactor Industrial Fermenter

Bioreactor manufacturer for probiotics

- UMA PHARMATECH MACHINERY-UPM

- July 12, 2025

- Industrial Bioreactor Industrial Fermenter

SS316L industrial bioreactor

- UMA PHARMATECH MACHINERY-UPM

- July 9, 2025

- Industrial Bioreactor Industrial Fermenter

Biotech bioreactor system manufacturer

- UMA PHARMATECH MACHINERY-UPM

- July 9, 2025

- Industrial Bioreactor Industrial Fermenter

Bioreactor-Manufacturer-Suppliers

- uma Pharmatech Machinery

- May 11, 2025

- Autoclavable Bioreactor Benchtop Bioreactor bioreactor bioreactor Exporters Bioreactor manufacturer bioreactor suppliers Glass Bioreactor Industrial Bioreactor Laboratory Bioreactor Pilot Scale Bioreactor Stainless Steel Bioreactor

Fermenter-Manufacturer-Suppliers

- uma Pharmatech Machinery

- May 11, 2025

- autoclavable Fermenter benchtop fermenter fermenter fermenter Exporters fermenter manufacturer fermenter Suppliers Glass fermenter Industrial Fermenter laboratory fermenter Pilot Scale fermenter stainless steel fermenter

Stainless Steel Fermenter Manufacturer

- uma Pharmatech Machinery

- May 11, 2025

- stainless steel fermenter

Glass Fermenter Manufacturer

- uma Pharmatech Machinery

- May 11, 2025

- Glass fermenter

Benchtop Fermenter Manufacturer

- uma Pharmatech Machinery

- May 11, 2025

- benchtop fermenter

Stainless Steel Bioreactor Manufacturer

- uma Pharmatech Machinery

- May 11, 2025

- Stainless Steel Bioreactor

Glass Bioreactor Manufacturer

- uma Pharmatech Machinery

- May 11, 2025

- Glass Bioreactor

Benchtop Bioreactor Manufacturer

- uma Pharmatech Machinery

- May 11, 2025

- Benchtop Bioreactor

Autoclavable Bioreactor Manufacturer

- uma Pharmatech Machinery

- May 11, 2025

- Autoclavable Bioreactor

Autoclavable Fermenter Manufacturer

- uma Pharmatech Machinery

- May 11, 2025

- autoclavable Fermenter

Fermenter Exporters

- uma Pharmatech Machinery

- May 11, 2025

- fermenter Exporters

Bioreactor Exporters

- uma Pharmatech Machinery

- May 11, 2025

- bioreactor Exporters

Bioreactor suppliers

- uma Pharmatech Machinery

- May 11, 2025

- bioreactor suppliers

Fermenter suppliers

- uma Pharmatech Machinery

- May 11, 2025

- fermenter Suppliers

Industrial Fermenter manufacturers

- uma Pharmatech Machinery

- May 11, 2025

- Industrial Fermenter

Pilot Scale Fermenter manufacturers

- uma Pharmatech Machinery

- May 11, 2025

- Pilot Scale fermenter

Laboratory Fermenter manufacturers

- uma Pharmatech Machinery

- May 11, 2025

- laboratory fermenter

Laboratory Bioreactor manufacturers

- uma Pharmatech Machinery

- May 11, 2025

- Laboratory Bioreactor

Pilot Scale Bioreactor manufacturers

- uma Pharmatech Machinery

- Pilot Scale Bioreactor

Industrial Bioreactor manufacturers

- uma Pharmatech Machinery

- Industrial Bioreactor