Fermentation Plant Manufacturer

In Fermentation Plant Manufacturer in India Uma Pharmatech Machinery is One Of The Leading Manufacturer and Exporter in India. We Are Manufacturing Industrial Fermentation Plant Turnkey Solution For Various Industries Like:

- BioPharmaceutical

- Chemical

- Vaccine

- Api

- Intermediate

- Agro Chemical

- Biofertilizer and Biopesticides

- Pre and Pro biotics

- Enzymes

- Proteins

- Nutrition

Fermentation is an important process in many industries, including food and beverage, pharmaceuticals, and biofuels. That is why we provide a top-of-the-line fermentation system to assist you in achieving the best possible results.

Uma Made fermentation system is designed to provide an ideal environment for microorganism growth and reproduction, which is required for the fermentation process. A vessel, an agitator, a heating and cooling system, and a control system comprise our system.

The Fermentation Tank is made of high-quality stainless steel, which ensures the system’s durability and longevity. The agitator is designed to efficiently mix the vessel’s contents, ensuring that the microorganisms have access to all of the nutrients they require for optimal growth and reproduction.

Manufacturer of Fermenter in India

As global concern about climate change grows, an increasing number of people are looking for long-term solutions to reduce their carbon footprint. The use of fermentation plants, which convert organic waste into valuable resources such as biogas and fertilizer, is one such solution. UPM is dedicated to promoting the use of fermentation plants as a means of helping the environment and creating a more sustainable future.

What is a Fermentation Plant?

Bioreactor Manufacturer in India

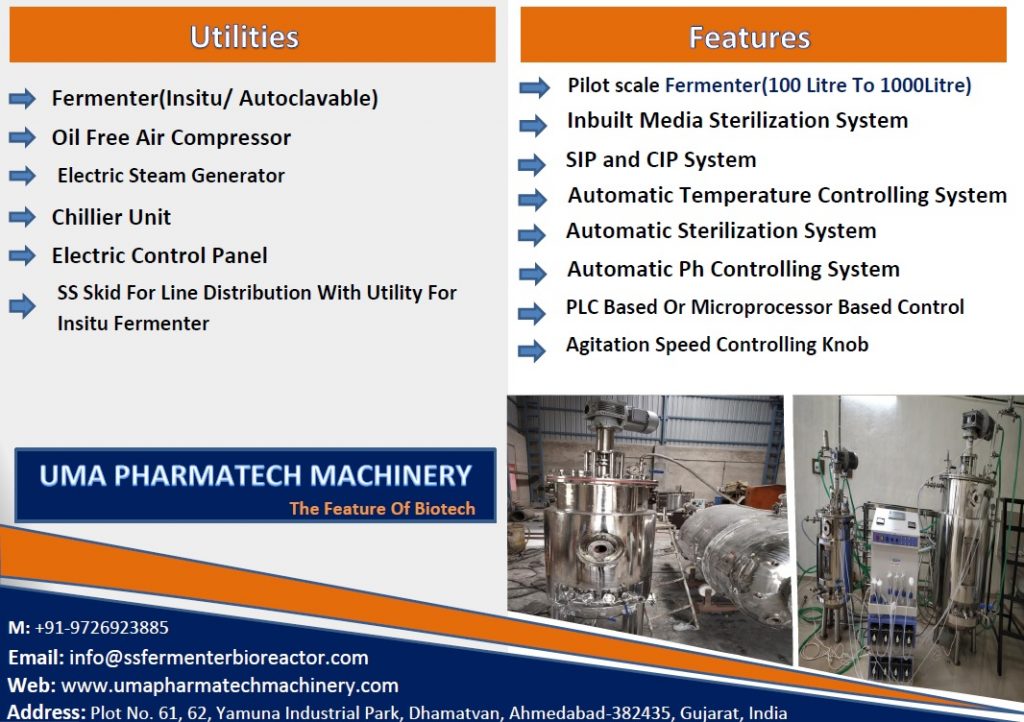

The heating and cooling system is an important part of our fermentation system because it keeps the temperature constant throughout the process. This is critical because microorganism growth and reproduction are highly dependent on environmental temperature.

Uma Pharmatech control system is designed to give you precise control over all aspects of the fermentation process, such as temperature, agitation speed, and nutrient supply. This enables you to achieve the best results possible with the least amount of effort.

We offer a variety of accessories and add-ons to help you optimize your fermentation process in addition to our fermentation system. These include sensors for monitoring the fermentation process as well as software for data analysis.

UPM fermentation system is simple to use, clean, and maintain. It’s also highly customizable, so you can tailor it to your specific needs and specifications. Our fermentation system can help you achieve the best possible results whether you are a small startup or a large corporation.

Automatic Control Industrial Fermenter

Uma Pharmatech Machinery’s legacy stretches far beyond the bustling streets of Surat. As an industrial fermenter manufacturer in India, their influence resonates throughout the nation’s industrial heartlands. From the pharmaceutical hubs to the burgeoning biotech clusters, their fermenters become catalysts for progress, fostering a culture of self-reliance and technological evolution.

Cost of Fermenter For Industrial 1000L-100L

Considering the cost of fermenters goes beyond financial considerations. It’s an investment in progress, innovation, and industrial advancement. Uma Pharmatech Machinery understands this profound impact, offering fermenters that embody not only engineering excellence but also the potential for transformative change across sectors.

Download Quotation Of Industrial Fermenter

Automatic Control Laboratory Bioreactor

The producers of laboratory fermenters are a significant force in India’s scientific and industrial scene. They are experts in creating state-of-the-art fermentation machinery, promoting progress in biotechnology, pharmaceuticals, and research. To advance India’s advancement in a variety of scientific fields, these manufacturers demonstrate knowledge, ensuring quality, innovation, and effective solutions.

Download Quotation of Lab Fermenter

Specification of Insitu SS Fermenter For Laboratory

· 10 Litter SS Fermenter · Pt-100 Temperature Sensor and Digital Temperature Measurement System · Mini Oil Free Air Compressor(1 Hp) Suitable For 10 Litter Fermenter · Air Flow Control Through Rota meter · Electromagnetic Agitator Speed Control Knob (RPM Controller) with control panel · Electric Steam Generator (All Ms Body-50Litter Tank with Water Level Tube)(Manual Feed Water-6kw)

| 1 Nos | info@umapharmatechmachinery.com |

Automatic Ph. Measurement & Control System | 1 Nos | Extra Cost On Request |

Do Sensor(Indian Made) | 1 Nos | Extra Cost On Request |

10L SS Fermenter With Oil Free Air Compressor and Electric Steam Boiler unit

Agitation Stirring Arrangement

Top Mounted Agitator Shaft With Lab Seal and 2 Nos Adjustable Ruston Turbine

- PMDC Motor(RPM 1200)

- DC/Ac Drive For Agitator Speed Controller Knob

Aeration Control System

- Air Flow Rota meter With Manual Flow Control Valve

Pressure Control System

- Pressure Regulator For Process Pressure Control

Digital Temperature Measurement System

- Pt -100 Temperature Sensor For Accurate Temperature Measurement

- Digital Temperature Indicator

Control Panel

- Powder Coated Control Panel With Various Panel Mounted Accessories, Instruments and Controller

Fermenter Construction and Specification

Total Volune:10 Litter

Working Volume:70% Of Total Volume

L/d Ratio : 1: 1.5 to 2.5

Contact Part: SS 316L

Non Contact Parts: SS 304

Contact Part: SS 316L

Outer Finish : Matt Finished

Inner Finish : 220 Grit Finish

Motor : PMDC

Max. Output RPM Speed : 1200

Speed Controlling: Using Micro controller

Temperature Sensor : PT-100 Type(Sterilizable)

Temperature Controlling System : PID Control Digital Display

Air Inlet Filter : 0.2 Micron PP Filter

Air Outlet Filter : 0.2 Micron PP Filter

Air Outlet : Through Shell Tube Type Condenser ( Heat Exchanger)

Spurger System : Ring Type Air Spurger System At Bottom

Mechanical Seal : For Zero Contamination and Reduce Air Leakage

Baffle : 4 Nos( Size Vessel Dia/10)

Adjustable Impeller : 2 Nos Of Adjustable Ruston Turbine( Six Blade)(Vessel Dia/3)

Automatic Control Pilot Scale Fermenter

In India, pilot scale fermenter manufacturers are vital catalysts for innovation. They produce advanced fermentation systems, crucial for scaling up biotechnological processes. These manufacturers drive research, bridging the gap between lab experiments and large-scale production, bolstering sectors like pharmaceuticals and biofuels, and contributing significantly to India’s scientific and economic growth.

Specification of Pilot Scale Fermenter

Download Pilot Cale Fermenter Prize List

Industrial and Pilot Scale Fermentation System Manufacturing Layout

- Automatic and Semi automatic Control and Maintain Parameter

- PH control through acid pump and base pump Feed control throught batch using Peristatic pump automatically.

- Control range 1-14pH, measure Accuracy ± 0.1 pH Auto control Accuracy±0.5

- It has automatic alarm Programming in PLC System

- pH sensor and transmission controlling line, E& H Or Toshniwal

Dissolve Oxygen Auto Control

- On-line check and measure, Polerographic with digital Control system

- Validation 0-21% or 0-10000%, Accuracy ±0.5%;

- It has automatic Signal function for Alert

- Dissolve OXYGEN SERIALIZABLE sensor and Controller With Standard Bradley James.

Automatic Foam level Measurement

manual or semi Automatically Analyze and automatically Control With SCADA Programming Legguage

Stainless steel gtade 304/ Silicon Tube peristaltic pump automatically add anti foamer In Vessel Or Fermenter.

Feed control

Automatically control and automatically alarm

Stainless steel electrode check, peristaltic pump automatically feeding

Temp. control

- PLC CONTROLLING fully Accurate signal Receving Transmitter, Analog control System.

- Chilling water Circulate automatically with SCADA Timer control And temperature Measurement

- Measure range 200 degree, control range 10- 50degree,control Accuracy±0.2 degree

- Pt-100 or c type temperature controlling Sensor.

- system with electrical heater to control the temp inside vessel

- Cooling Water Supply For Temperature Control In Fermentation Plant For Manufacturing

- Panumatic and hydraulic solenoid valve to control Temperature and Other Parameter

Agitation Controllable speed

Automatically control Impeller Speed For Gas Mixing Through Ruston Turbine

L&T Hifh Frequenct Hearts frequency 0-50 hz to adjust the speed of DC DRIVE

Pressure Control With Temperature

Automatic adjusting with pressure gauge and Pressure Transmitter and Automatic valve Made IQS OR MARK OR DEN fORCE Of pt-36 model

Industrial Fermentation Plant Manufacturer and Exporter In india We Are Manufacturing Fermentation Plant For Various Product Like

How Fermentation Plants Work:

Anaerobic digestion, a natural process that occurs in the absence of oxygen, is used by fermentation plants to break down organic waste materials. There are several stages to the process:

Organic waste materials such as food scraps, animal manure, and plant matter are collected and prepared for digestion as feedstock.

The prepared feedstock is then fed into a digester, where microorganisms break down the organic matter to produce biogas and digestate.

Upgrading Biogas: Biogas is typically composed of methane and carbon dioxide, with trace amounts of other gases. The biogas is purified and upgraded to remove impurities like carbon dioxide before being used to generate electricity or heat.

Digestate Processing: During digestion, the digestate is separated into a liquid and solid fraction. The liquid fraction is typically used as fertilizer, whereas the solid fraction can be processed further to produce high-quality compost.

What is Enzyme Production?

UPM Manufacturer and Export its product and services for fermentation plant setup in following countries below

- Bangladesh

- USA

- UK

- Brazil

- Thailand

- UAE

- Oman

- turkey

- Indonesia

- Switzerland

- Germany

- Russia

- Brazil

- Sweden

- Uganda

- Malesia

- Nigeria

- Nepal

- Spain

- Qatar

- Vietnam

- Italy

- Kenya

- Australia

- Austria

- Angola

- South Africa

- Egypt

- Netherland

- Romania

- Kuwait

- Iran

- Tanzania

- Syria

- Sudan

- Vietnam

- Ethiopia

- Jordan

- Argentina

- Libya

- Liberia

- Belgium

- Lebanon

- Mali

- Zambia

- Mexico

- Rwanda

Applications of Fermentation Plants:

For anyone looking to optimise their fermentation process, our fermentation system is the best option. It is the ideal tool for achieving the best results, thanks to its high-quality components, precise control system, and wide range of accessories and add-ons. If you’re ready to take your fermentation process to the next level, get in touch with us today to learn more about our system and how it can help you meet your objectives.

Fermentation plants provide a long-term solution to organic waste management by reducing greenhouse gas emissions, generating renewable energy, and promoting healthy soil and plant growth. Uma Pharmatech Machinery is dedicated to promoting the use of fermentation plants as a means of achieving a more sustainable future. Contact us today to learn more about how we can assist you with the installation of a fermentation plant at your facility.

Contact US

- 61, Yamuna Industrial Park, Opp. Sardar Patel Estale, Vanch-dhamatvan Road, Dhamatvan, Ahmedabad, Gijarat, India-382435

- +91-9726923885, +91-8866137364

- info@umapharmatechmachinery.com

- info@fermenterbioreactor.com

- umapharmatechmachinerys@gmail.com

Quick Links