Fermenter For Biofertilizer Plant Manufacturer in Maharashtra

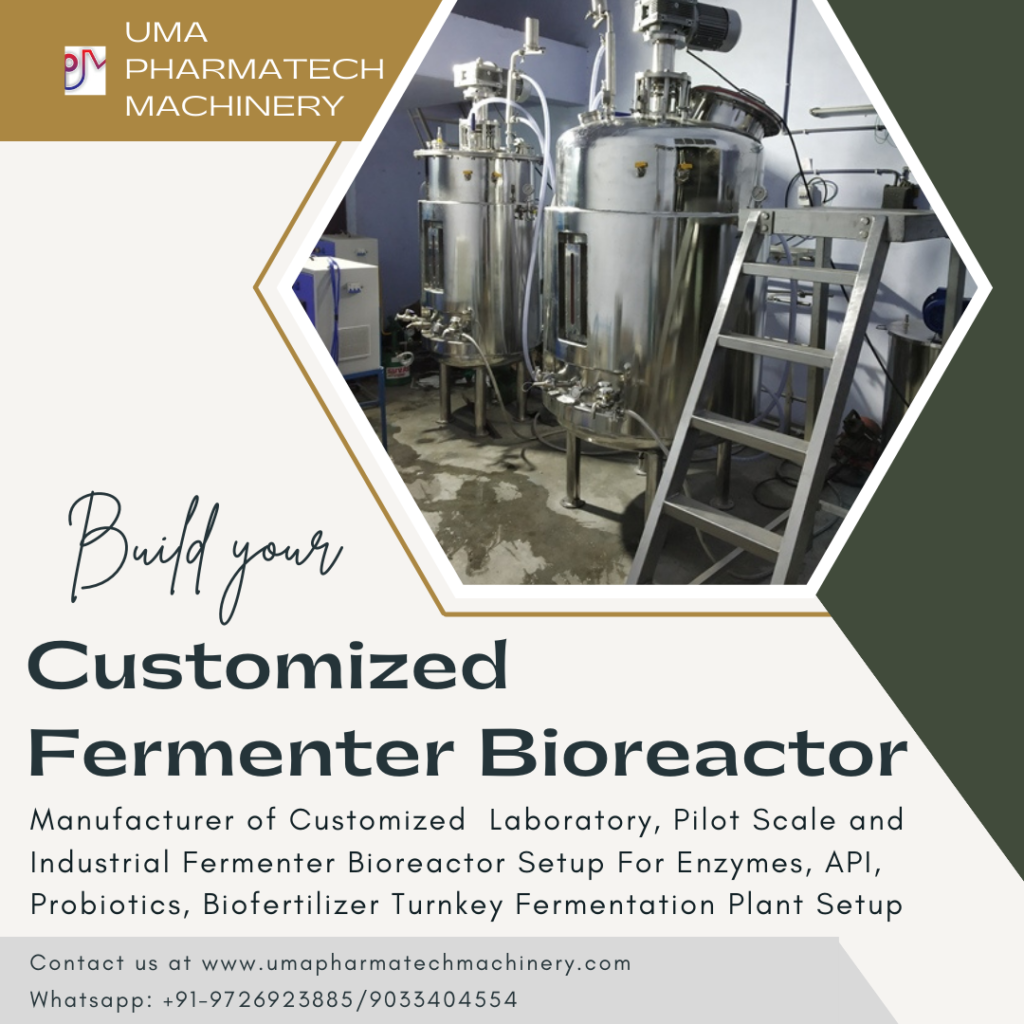

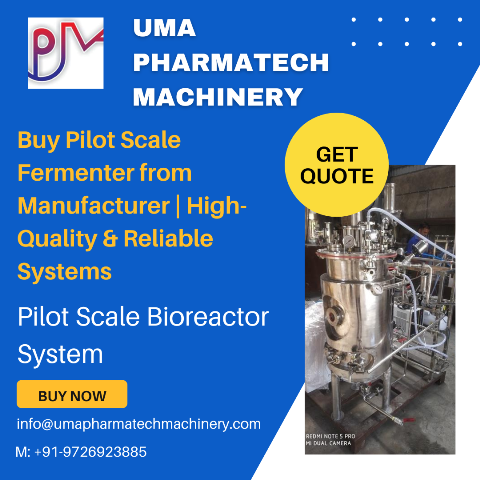

When it comes to finding the top fermenter For Biofertilizer Plant manufacturer in Maharashtra, look no further. Our company has established a strong presence in the bioreactor and fermenter manufacturing industry, with a reputation for excellence and innovation. We take pride in being a leading player in this field, catering to diverse regions and clientele.

Our journey as a bioreactor manufacturer started in Dehradun, and since then, we have expanded our operations to various locations, including Delhi, Mumbai, and even Russia. This extensive network of manufacturing facilities enables us to serve clients across the globe efficiently.

In Maharashtra, where industrial growth is thriving, our presence as a fermenter manufacturer is particularly prominent. We offer state-of-the-art fermenters designed to meet the needs of various industries. Whether you’re in Mumbai, Pune, or any other part of the state, our products are easily accessible.

If you’re searching for a reliable fermenter or bioreactor manufacturer in Maharashtra, our company’s commitment to quality and customer satisfaction makes us the top choice. With our wide range of products and a strong presence in the region, we are your trusted partner for all your bioprocessing equipment needs.

For more details, please visit our dedicated pages:

- Bioreactor Manufacturers in Dehradun

- Fermenter Manufacturers in Delhi

- Fermenter Manufacturer in Mumbai

We invite you to explore our website and discover how our cutting-edge products and services can benefit your business. Choose the best in the industry, choose us – your trusted top fermenter manufacturer in Maharashtra.

Top Manufacturer of Bioreactor in Pune-Maharashtra

Setting Up a Bio Fertilizer Manufacturing Plant: Leveraging Uma Pharmatech Fermenters for Bio Fertilizers Manufacturing

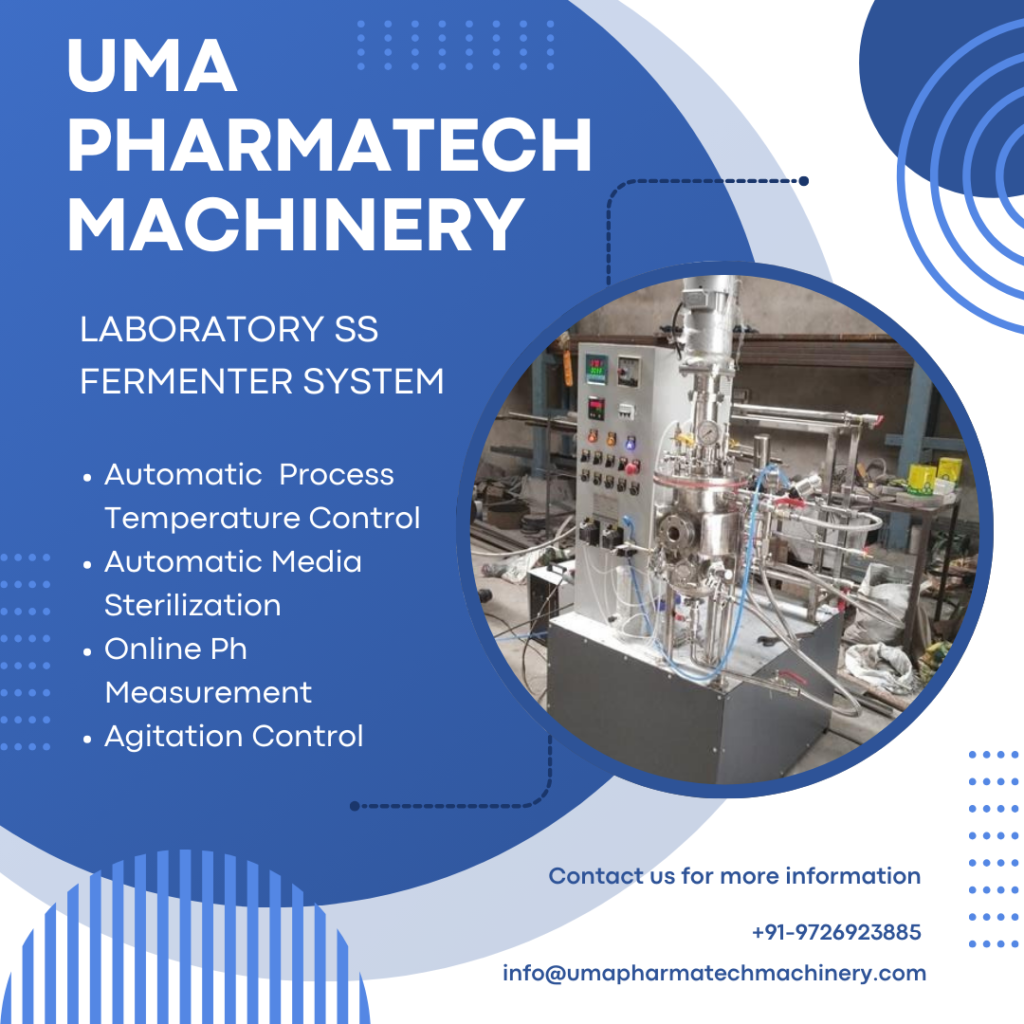

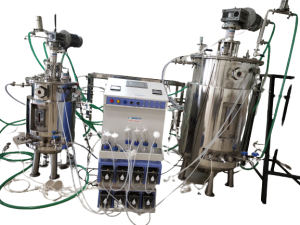

Biofertilizers are eco-friendly alternatives to chemical fertilizers, enriching the soil with microorganisms that enhance plant growth. Fermentation is a critical process in biofertilizer production, where microorganisms are cultivated in controlled environments to multiply and produce beneficial compounds. UPM Fermenters for Bio Fertilizers Manufacturing provide state-of-the-art solutions for optimizing these fermentation processes.

Benefits of Uma Pharmatech Machinery Fermenters Bioreactors

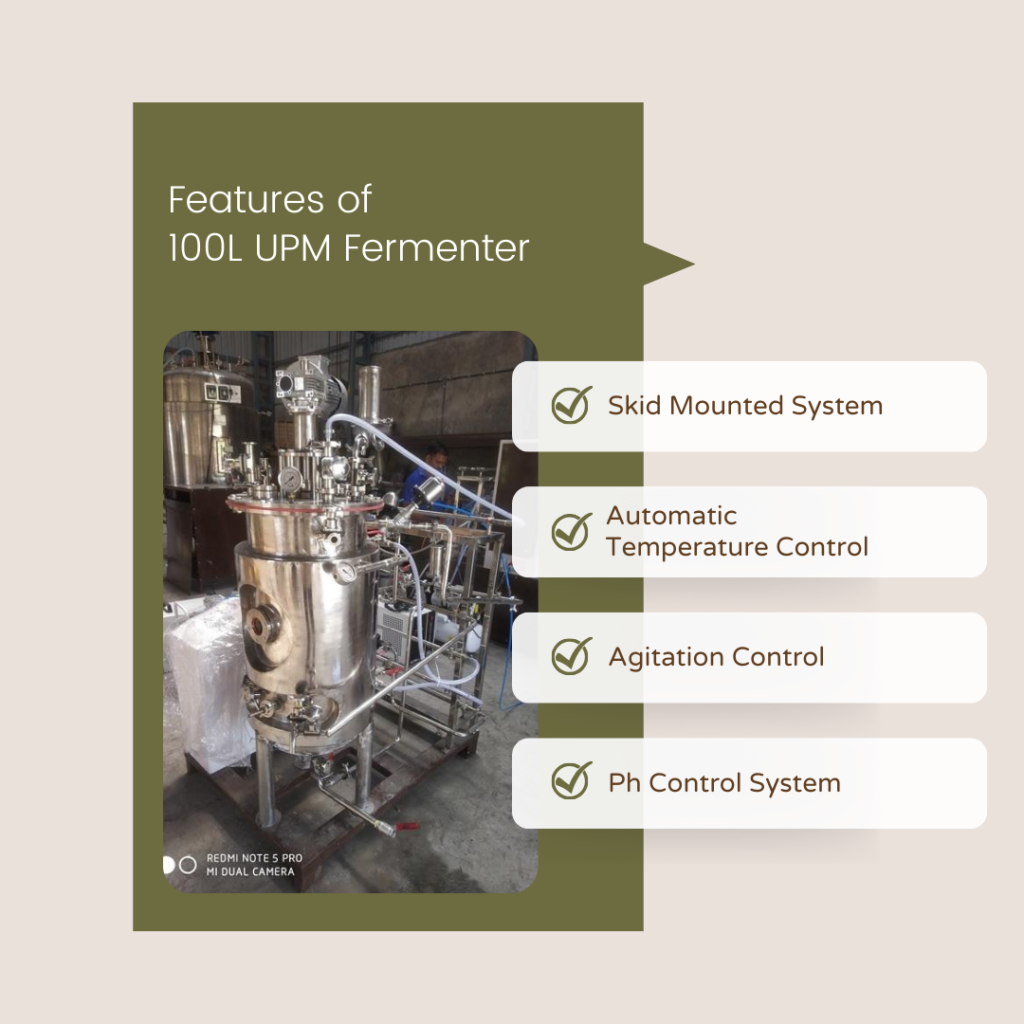

Uma Pharmatech Machinery Fermenters Bioreactors are designed to maximize efficiency and yield in biofertilizer production. These bioreactors offer precise control over environmental conditions such as temperature, pH, and aeration, ensuring optimal growth of microbial cultures. The robust design and advanced features of UPM fermenters lead to consistent and high-quality biofertilizer products, making them an essential component for any biofertilizer manufacturing plant.

Procuring UPM Fermenters

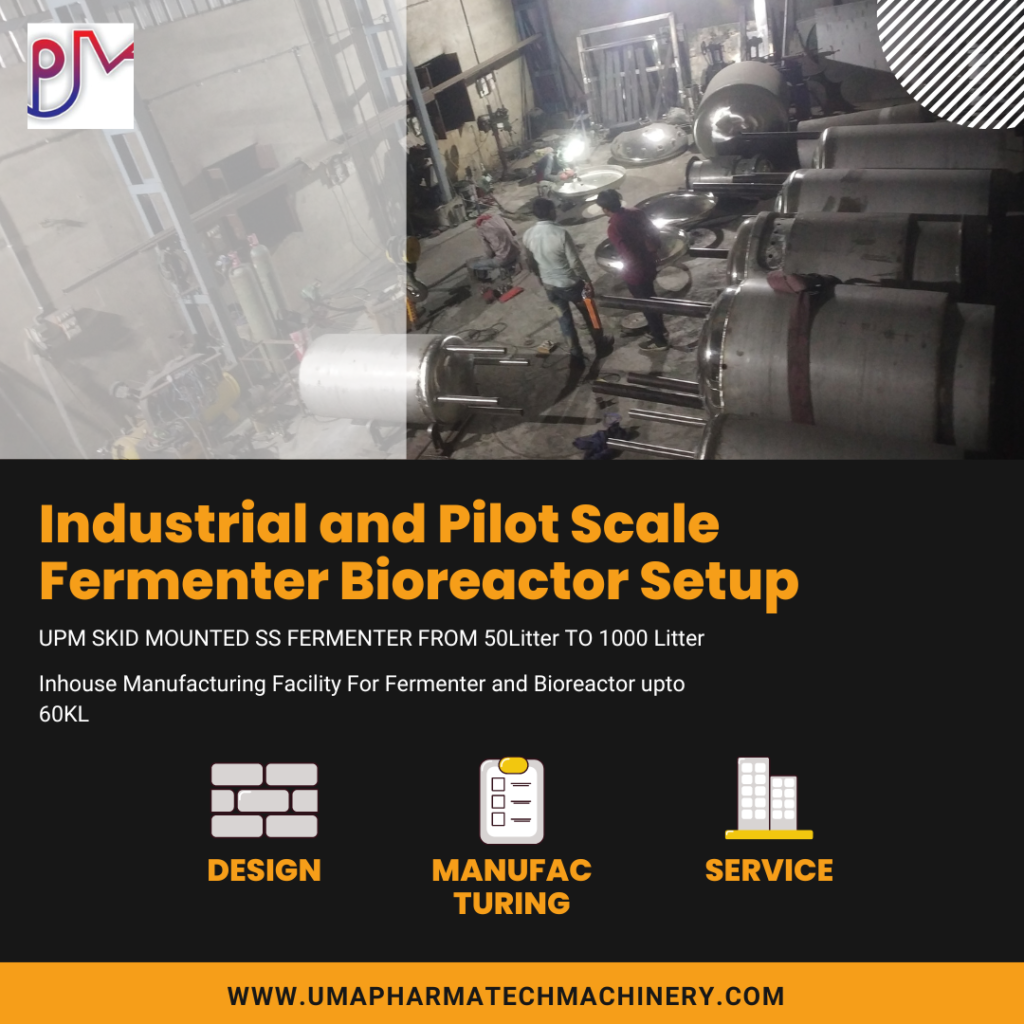

A successful Fermentation Facility Setup involves careful planning and execution. The facility must be equipped with the necessary fermenters, bioreactors, and support systems such as sterilization, cooling, and agitation. Ensuring a contamination-free environment is crucial for maintaining the purity of microbial cultures. Proper layout and design of the facility contribute to efficient workflow and scalability.

Bioreactor for Microbial Cultivation

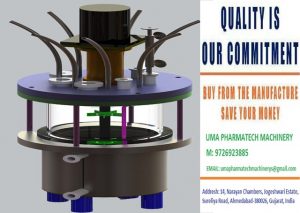

A Bioreactor for Microbial Cultivation is at the heart of biofertilizer production. These specialized vessels provide an ideal environment for the growth and activity of microorganisms. Features such as automated monitoring and control systems, along with efficient mixing and aeration mechanisms, are essential for optimizing microbial cultivation and ensuring high productivity.

Biofertilizer Manufacturing Plant Project Report 2024 Setup Layout, Economics, and Unit Cost | LinkedIn

A comprehensive Biofertilizer Manufacturing Plant Project Report 2024 is indispensable for setting up a successful biofertilizer manufacturing unit. This report details the setup layout, economics, and unit costs involved in the project. Accessing such information on platforms like LinkedIn helps in understanding the financial and operational aspects, guiding informed decision-making.

Project Details, Requirements and Costs Involved

When embarking on a biofertilizer manufacturing venture, understanding the Project Details, Requirements and Costs Involved is crucial. These details include the type of biofertilizers to be produced, the scale of production, and the technology to be used. Evaluating these aspects helps in planning the investment and operational strategy effectively.

Plant and Machinery-Capital Cost of the Project

Consulting with experts like those at MITCON Biotechnology & Pharmaceutical Technology Business Incubator (TBI) Center provides valuable insights into biofertilizer production. Their Consultancy Project Profile offers guidance on the latest technologies, regulatory requirements, and market trends, ensuring that your project aligns with industry standards.

The selection of Plant and Machinery is a critical aspect of establishing a biofertilizer manufacturing plant. This includes choosing the right fermenters, bioreactors, and ancillary equipment such as sterilizers and mixers. Advanced machinery ensures efficient and consistent production, reducing operational costs and enhancing product quality.

Understanding the Manufacturing Process and Source of Technology is vital for producing high-quality biofertilizers. This involves selecting appropriate microbial strains, optimizing fermentation conditions, and employing cutting-edge technologies. Reliable sources of technology and expertise play a significant role in streamlining the production process and achieving desired outcomes.

Calculating the Capital Cost of the Project is essential for budgeting and financial planning. This includes costs for equipment, facility setup, raw materials, and operational expenses. Accurate cost estimation ensures that the project is financially viable and sustainable in the long run.

A List of Commonly Produced Bio-Fertilizers in India includes various types such as nitrogen-fixing bacteria, phosphate-solubilizing bacteria, and mycorrhizal fungi. These biofertilizers cater to different agricultural needs, enhancing soil fertility and crop yield.

Fermenter Manufacturer-Maharashtra

Fermenter Manufacturer in Andhra Pradesh

Fermenter Manufacturer in Assam

Fermenter Manufacturer in Chhattisgarh

Fermenter Manufacturer in Goa

Fermenter Manufacturer in Gujarat

Fermenter Manufacturer in Haryana

Fermenter Manufacturer in Himachal Pradesh

Fermenter Manufacturer in Jharkhand

Fermenter Manufacturer in Karnataka

Fermenter Manufacturer in Kerala

Fermenter Manufacturer in Madhya Pradesh

Fermenter Manufacturer in Maharashtra

Fermenter Manufacturer in Odisha

Fermenter Manufacturer in Punjab

Fermenter Manufacturer in Rajasthan

Fermenter Manufacturer in Sikkim

Fermenter Manufacturer in Tamil Nadu

Fermenter Manufacturer in Telangana

Fermenter Manufacturer in Tripura

Fermenter Manufacturer in Uttar Pradesh

Fermenter Manufacturer in Uttarakhand

Fermenter Manufacturer in West Bengal

Biofertilizer Manufacturing Business. How to Start Biofertiliser Production Unit. Profitable Small Business Ideas in India. | PPT

Starting a Biofertilizer Manufacturing Business involves understanding market demand, production processes, and regulatory requirements. Detailed presentations, like those found in Profitable Small Business Ideas in India | PPT, provide step-by-step guidance on setting up and operating a biofertilizer production unit.

A detailed Biofertilizer Manufacturing Plant Report: Setup & Cost outlines the infrastructure, machinery, and financial investment required for establishing a biofertilizer plant. This report serves as a roadmap, helping entrepreneurs navigate the complexities of plant setup and cost management.

The Biofertilizer Manufacturing Plant Project Report 2024 provides comprehensive insights into industry trends, plant setup, machinery, raw materials, investment opportunities, cost, and revenue. This report is a valuable resource for investors and entrepreneurs looking to capitalize on the growing demand for biofertilizers.

A well-documented Biofertilizer Manufacturing Plant Project Report is essential for securing funding and ensuring project success. It covers all aspects of the project, from initial planning to operational details, providing a clear picture of the business potential and profitability.