Industrial Production fermenter

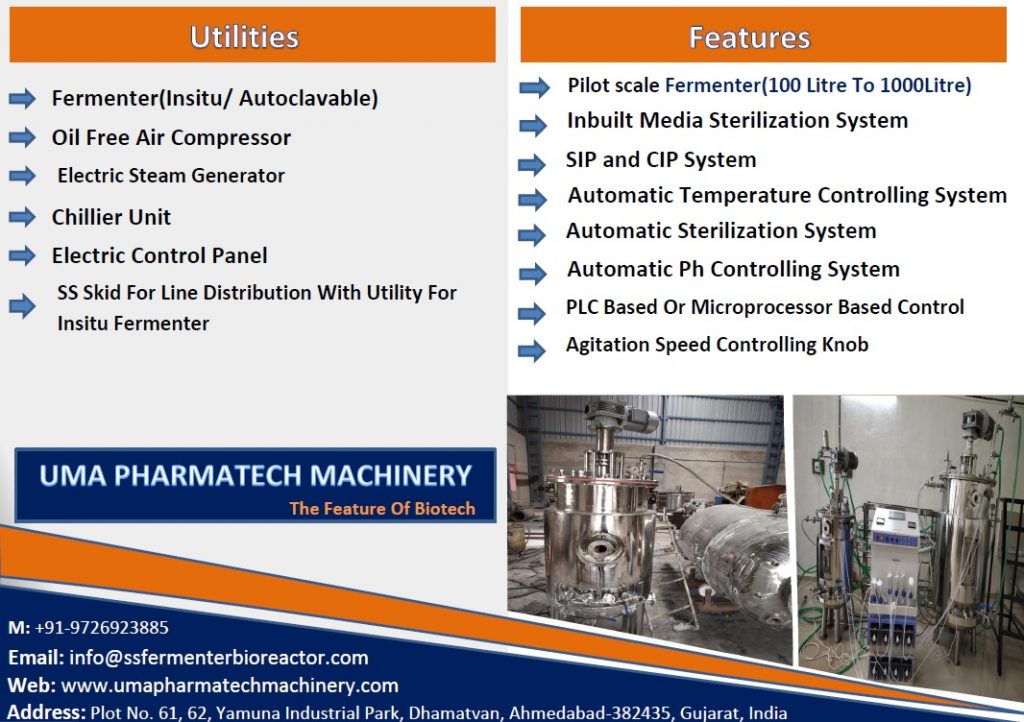

Upm Industrial Production Fermenter is Design To Meet Pharmaceutical and Biotech Industries Application. Uma Pharmatech Industrial production fermenter and bioreactor is Used In Various Production Unit Like:

probiotics Manufacturing, Biofertilizer Manufacturing, Bio Pesticides Manufacturing, Antibiotics Manufacturing, and Many More.

Indian Exporter Of Fermenter and Bioreactors

For Manufacturing Of Production scale Fermenter Uma Pharmatech Machinery Gives Best and Affordable Solution For Bio Process Engineer. We Have More Than 15+ Years Of Experience in Research, Design, Innovation, and Manufacturing, Export From India, if industrial fermenter implementation of production fermenter in this bio engineering Field and bio fermenter manufacturer in Gujarat.

Uma Pharmatech Machinery Is gives complete plant project for fermenter and bioreactor with all utilities for pilot and production scale. UPM Industrial Fermenter is very Easy To Operate and Make Batch For Microbiologist & scientist.

Uma Pharmatech Gives Automated Batch Record and Data Logging Facilities in PLC Programmable Control System For Industrial and Pilot scale Bioreactor or Fermenter.

Fermenters are specialized containers designed to make it easier to grow cells or bacteria under controlled circumstances. They’re also known as fermentation tanks or vessels. In these tubes, bacteria have an excellent environment in which to carry out metabolic processes that culminate in the production of enzymes. Bioreactors are more advanced systems that use agitation, aeration, and pH regulation to maximize enzyme synthesis while maintaining microbial growth. These advancements have drastically altered the enzyme manufacturing process.

UPM Provide Service For Industrial fermenter for various old designed fermenter and renovate to new and advances design automated fermenter. This services Help To Customer For Sell old Fermenter To Use With Latest Advanced Design Automatic Fermenter For Production Scale and Industrial Scale.

Fermenters and bioreactors are utilized for process optimization and feasibility studies at the pilot stage. These systems enable parameter fine-tuning and process optimization by bridging the gap between laboratory-scale research and full-scale manufacturing. Scientists and producers can test various growth conditions, improve medium formulations, and evaluate the general viability and scalability of enzyme manufacturing processes using pilot-scale fermenters and bioreactors. Laboratory bioreactors are essential for producing enzymes in the lab, where initial research and development take place.

We Supply bioreactor for pilot scale and production scale fermentation system with automatic Controlling.

Working with reputable and experienced suppliers helps maximize the capacity of fermenters and bioreactors to synthesize enzymes. There are numerous different suppliers of fermenters and bioreactors designed for enzyme manufacturing facilities on the market, though specific business names won’t be included in this article. Since these suppliers are aware of the specific needs of the enzyme manufacturing business, they offer cutting-edge products and services to guarantee top performance and productivity.

It is Necessary to take into account elements like the supplier’s track record, proficiency in bioprocess engineering, quality assurance methods, and after-sale support when selecting suppliers for a biofertilizer and enzyme production plant. Examining customer feedback and testimonials can provide insightful information about a supplier’s standing and customers’ contentment.

Automatic Control Industrial Fermenter

Uma Pharmatech Machinery’s legacy stretches far beyond the bustling streets of Surat. As an industrial fermenter manufacturer in India, their influence resonates throughout the nation’s industrial heartlands. From the pharmaceutical hubs to the burgeoning biotech clusters, their fermenters become catalysts for progress, fostering a culture of self-reliance and technological evolution.

Cost of Fermenter For Industrial 1000L-100L

Considering the cost of fermenters goes beyond financial considerations. It’s an investment in progress, innovation, and industrial advancement. Uma Pharmatech Machinery understands this profound impact, offering fermenters that embody not only engineering excellence but also the potential for transformative change across sectors.

Download Quotation Of Industrial Fermenter

Automatic Control Laboratory Bioreactor

The producers of laboratory fermenters are a significant force in India’s scientific and industrial scene. They are experts in creating state-of-the-art fermentation machinery, promoting progress in biotechnology, pharmaceuticals, and research. To advance India’s advancement in a variety of scientific fields, these manufacturers demonstrate knowledge, ensuring quality, innovation, and effective solutions.

Download Quotation of Lab Fermenter

Specification of Insitu SS Fermenter For Laboratory

· 10 Litter SS Fermenter · Pt-100 Temperature Sensor and Digital Temperature Measurement System · Mini Oil Free Air Compressor(1 Hp) Suitable For 10 Litter Fermenter · Air Flow Control Through Rota meter · Electromagnetic Agitator Speed Control Knob (RPM Controller) with control panel · Electric Steam Generator (All Ms Body-50Litter Tank with Water Level Tube)(Manual Feed Water-6kw)

| 1 Nos | info@umapharmatechmachinery.com |

Automatic Ph. Measurement & Control System | 1 Nos | Extra Cost On Request |

Do Sensor(Indian Made) | 1 Nos | Extra Cost On Request |

10L SS Fermenter With Oil Free Air Compressor and Electric Steam Boiler unit

Agitation Stirring Arrangement

Top Mounted Agitator Shaft With Lab Seal and 2 Nos Adjustable Ruston Turbine

- PMDC Motor(RPM 1200)

- DC/Ac Drive For Agitator Speed Controller Knob

Aeration Control System

- Air Flow Rota meter With Manual Flow Control Valve

Pressure Control System

- Pressure Regulator For Process Pressure Control

Digital Temperature Measurement System

- Pt -100 Temperature Sensor For Accurate Temperature Measurement

- Digital Temperature Indicator

Control Panel

- Powder Coated Control Panel With Various Panel Mounted Accessories, Instruments and Controller

Fermenter Construction and Specification

Total Volune:10 Litter

Working Volume:70% Of Total Volume

L/d Ratio : 1: 1.5 to 2.5

Contact Part: SS 316L

Non Contact Parts: SS 304

Contact Part: SS 316L

Outer Finish : Matt Finished

Inner Finish : 220 Grit Finish

Motor : PMDC

Max. Output RPM Speed : 1200

Speed Controlling: Using Micro controller

Temperature Sensor : PT-100 Type(Sterilizable)

Temperature Controlling System : PID Control Digital Display

Air Inlet Filter : 0.2 Micron PP Filter

Air Outlet Filter : 0.2 Micron PP Filter

Air Outlet : Through Shell Tube Type Condenser ( Heat Exchanger)

Spurger System : Ring Type Air Spurger System At Bottom

Mechanical Seal : For Zero Contamination and Reduce Air Leakage

Baffle : 4 Nos( Size Vessel Dia/10)

Adjustable Impeller : 2 Nos Of Adjustable Ruston Turbine( Six Blade)(Vessel Dia/3)

Automatic Control Pilot Scale Fermenter

In India, pilot scale fermenter manufacturers are vital catalysts for innovation. They produce advanced fermentation systems, crucial for scaling up biotechnological processes. These manufacturers drive research, bridging the gap between lab experiments and large-scale production, bolstering sectors like pharmaceuticals and biofuels, and contributing significantly to India’s scientific and economic growth.

Specification of Pilot Scale Fermenter

Download Pilot Cale Fermenter Prize List

What is The Price Of Fermentor and Bioreactor?

Biofertilizer Plant Turnkey Solution | UMA PHARMATECH MACHINERY

- uma Pharmatech Machinery

- July 25, 2025

- biofertilizer plant setup Bioreactor for biofertilizer fermenter for biofertilizer

Automatic bioreactor manufacturer

- UMA PHARMATECH MACHINERY-UPM

- July 3, 2025

- Industrial Bioreactor Industrial Fermenter

- automatic bioreactor manufacturer, enzyme fermenter with SCADA, industrial bioreactor India, UMA PHARMATECH MACHINERY, bioreactor automation system

Bioreactor with SCADA control

- UMA PHARMATECH MACHINERY-UPM

- July 3, 2025

- Industrial Bioreactor Industrial Fermenter

GMP bioreactor manufacturer

- UMA PHARMATECH MACHINERY-UPM

- July 3, 2025

- Industrial Bioreactor Industrial Fermenter

Customized industrial bioreactor

- UMA PHARMATECH MACHINERY-UPM

- July 5, 2025

- Industrial Bioreactor Industrial Fermenter

Industrial bioreactor with PLC control

- UMA PHARMATECH MACHINERY-UPM

- July 5, 2025

- Industrial Bioreactor Industrial Fermenter

Industrial microbial fermenter

- UMA PHARMATECH MACHINERY-UPM

- July 5, 2025

- Industrial Bioreactor Industrial Fermenter

Bioreactor manufacturer for probiotics

- UMA PHARMATECH MACHINERY-UPM

- July 12, 2025

- Industrial Bioreactor Industrial Fermenter

SS316L industrial bioreactor

- UMA PHARMATECH MACHINERY-UPM

- July 9, 2025

- Industrial Bioreactor Industrial Fermenter

Biotech bioreactor system manufacturer

- UMA PHARMATECH MACHINERY-UPM

- July 9, 2025

- Industrial Bioreactor Industrial Fermenter

Bioreactor-Manufacturer-Suppliers

- uma Pharmatech Machinery

- May 11, 2025

- Autoclavable Bioreactor Benchtop Bioreactor bioreactor bioreactor Exporters Bioreactor manufacturer bioreactor suppliers Glass Bioreactor Industrial Bioreactor Laboratory Bioreactor Pilot Scale Bioreactor Stainless Steel Bioreactor

Fermenter-Manufacturer-Suppliers

- uma Pharmatech Machinery

- May 11, 2025

- autoclavable Fermenter benchtop fermenter fermenter fermenter Exporters fermenter manufacturer fermenter Suppliers Glass fermenter Industrial Fermenter laboratory fermenter Pilot Scale fermenter stainless steel fermenter

Fermenter Biofertilizer

- uma Pharmatech Machinery

- May 11, 2025

- biofertilizer plant setup Bioreactor for biofertilizer fermenter for biofertilizer

Bioreactor Biofertilizer

- uma Pharmatech Machinery

- May 11, 2025

- biofertilizer plant setup Bioreactor for biofertilizer

Biofertilizer Plant Setup

- uma Pharmatech Machinery

- May 11, 2025

- biofertilizer plant setup

Stainless Steel Fermenter Manufacturer

- uma Pharmatech Machinery

- May 11, 2025

- stainless steel fermenter

Stainless Steel Bioreactor Manufacturer

- uma Pharmatech Machinery

- May 11, 2025

- Stainless Steel Bioreactor

Industrial Fermenter manufacturers

- uma Pharmatech Machinery

- May 11, 2025

- Industrial Fermenter

Industrial Bioreactor manufacturers

- uma Pharmatech Machinery

- Industrial Bioreactor