Fermenter Manufacturer In Bengaluru

Fermenters are essential equipment used in biotechnology and pharmaceutical industries for fermentation processes. High-quality fermenters Manufacturers in Bengaluru that can withstand high temperatures, pressure, and sterilization processes are required by the industry In Bengaluru. In this article, we will go over the top features to look for when buying a fermenter and how to choose the best one for your needs.

Uma Pharmatech Machinery proudly spearheads the domain as the primary Fermenter Manufacturer and Supplier in Bengaluru and the leading Bioreactor Manufacturer and Supplier in Bengaluru. Their unwavering dedication to quality and state-of-the-art technology establishes Uma Pharmatech as the trusted source for these pivotal bioprocessing instruments within the city. Their Bengaluru-based manufacturing facility showcases cutting-edge production capabilities, catering to the soaring demand for fermenters and bioreactors.

Uma Pharmatech’s commitment to precision and reliability extends across industries, making them the preferred choice for bioreactor and fermenter solutions in Bengaluru. In this tech hub, Uma Pharmatech Machinery continues to set industry benchmarks, delivering superior products and service to meet the ever-evolving demands of bioprocessing.

Bioreactor Manufacturer in Bengaluru

Bioreactor Manufacturer In Bengaluru

In Maharashtra, a diverse and industrially vibrant state, bioreactor manufacturers play a pivotal role in supplying cutting-edge bioreactor systems. These manufacturers are dedicated to precision engineering, offering a comprehensive range of bioreactors for various industries, including biotechnology, pharmaceuticals, and research. With a strong focus on quality and innovation, they deliver bioreactors designed to efficiently cultivate microorganisms and cells, essential for biopharmaceutical production and scientific investigations.

Collaborating with a bioreactor manufacturer in Maharashtra ensures access to advanced bioreactor technology, meeting the stringent demands of industries committed to innovation and the development of cutting-edge products and pharmaceuticals.

Industrial Fermenter Manufacturer in Bengaluru

Industrial Fermenter Manufacturer in Bengaluru

In the bustling tech hub of Bengaluru, industrial fermenter manufacturers are key players in providing cutting-edge equipment for fermentation processes. These manufacturers specialize in crafting robust industrial fermenter systems that cater to diverse sectors, including biotechnology, pharmaceuticals, and research. Their precision engineering and commitment to quality ensure the reliable cultivation of microorganisms and cells, crucial for biopharmaceutical production and scientific experimentation. Collaborating with an industrial fermenter manufacturer in Bengaluru ensures access to advanced technology, contributing to the growth and advancement of these industries.

Industrial Bioreactor Manufacturer in Bengaluru

Bengaluru, a hub of innovation, hosts industrial bioreactor manufacturers dedicated to precision engineering. They specialize in crafting high-quality bioreactor systems for biotechnology, pharmaceuticals, and research sectors. Their innovative solutions enable efficient cultivation of microorganisms and cells, essential for biopharmaceutical production and scientific investigations. Collaborating with an industrial bioreactor manufacturer in Bengaluru ensures access to state-of-the-art bioreactor technology, contributing to advancements in these critical industries.

Industrial Fermenter Manufacturer in Karnataka

Across the state of Karnataka, industrial fermenter manufacturers are instrumental in providing robust equipment for fermentation processes. These manufacturers focus on crafting reliable industrial fermenter systems for various sectors, including biotechnology, pharmaceuticals, and research. Their precision engineering and commitment to quality ensure the efficient cultivation of microorganisms and cells, vital for biopharmaceutical production and scientific experimentation. Collaborating with an industrial fermenter manufacturer in Karnataka guarantees access to advanced technology, supporting the growth of these industries.

Industrial Bioreactor Manufacturer in Karnataka

In Karnataka, renowned for its industrial and scientific prowess, industrial bioreactor manufacturers excel in precision engineering. They specialize in crafting high-quality bioreactor systems for biotechnology, pharmaceuticals, and research sectors. Their innovative solutions enable the efficient cultivation of microorganisms and cells, crucial for biopharmaceutical production and scientific investigations. Collaborating with an industrial bioreactor manufacturer in Karnataka ensures access to state-of-the-art bioreactor technology, fostering advancements in these critical industries.

Industrial Fermenter Suppliers in Bengaluru

In the vibrant city of Bengaluru, industrial fermenter suppliers play a crucial role in providing equipment for fermentation processes. These suppliers offer a wide range of industrial fermenter systems designed for biotechnology, pharmaceuticals, and research. Their commitment to quality ensures dependable solutions for cultivating microorganisms and cells, essential for biopharmaceutical production and scientific experimentation. Collaborating with industrial fermenter suppliers in Bengaluru guarantees access to cutting-edge technology, supporting advancements in these industries.

Industrial Bioreactor Suppliers in Bengaluru

Bengaluru, a hub of innovation, hosts industrial bioreactor suppliers dedicated to providing high-quality bioreactor systems for biotechnology, pharmaceuticals, and research sectors. Their solutions enable efficient cultivation of microorganisms and cells, crucial for biopharmaceutical production and scientific investigations. Collaborating with industrial bioreactor suppliers in Bengaluru ensures access to state-of-the-art bioreactor technology, contributing to advancements in these critical industries.

Industrial Fermenter Suppliers in Karnataka

Across the state of Karnataka, industrial fermenter suppliers are vital in supplying equipment for fermentation processes. These suppliers offer a diverse range of industrial fermenter systems tailored to biotechnology, pharmaceuticals, and research. Their commitment to quality ensures reliable solutions for cultivating microorganisms and cells, essential for biopharmaceutical production and scientific experimentation. Collaborating with industrial fermenter suppliers in Karnataka guarantees access to advanced technology, supporting the growth and innovation of these industries.

Industrial Bioreactor Suppliers in Karnataka

In Karnataka, renowned for its industrial and scientific achievements, industrial bioreactor suppliers excel in providing high-quality bioreactor systems for biotechnology, pharmaceuticals, and research sectors. Their solutions enable efficient cultivation of microorganisms and cells, crucial for biopharmaceutical production and scientific investigations. Collaborating with industrial bioreactor suppliers in Karnataka ensures access to state-of-the-art bioreactor technology, fostering advancements in these critical industries.

Laboratory Fermenter Manufacturer in Bengaluru

Laboratory Fermenter Manufacturer in Bengaluru

In the vibrant tech city of Bengaluru, laboratory fermenter manufacturers lead the way in producing specialized equipment for laboratory-scale fermentation processes. These manufacturers are experts in crafting compact and precise laboratory fermenter systems suitable for a variety of applications, including biotechnology, pharmaceuticals, and research. Their dedication to quality ensures dependable solutions for cultivating microorganisms and cells, essential for biopharmaceutical production and scientific exploration. Collaborating with a laboratory fermenter manufacturer in Bengaluru provides access to advanced technology, supporting progress and innovation in these critical industries.

Laboratory Bioreactor Manufacturer in Bengaluru

Bengaluru, a hub of innovation, hosts laboratory bioreactor manufacturers dedicated to precision engineering. They specialize in designing high-quality laboratory bioreactor systems tailored to the needs of biotechnology, pharmaceuticals, and research sectors. Their innovative solutions enable efficient cultivation of microorganisms and cells, crucial for biopharmaceutical production and scientific investigations. Collaborating with a laboratory bioreactor manufacturer in Bengaluru ensures access to state-of-the-art bioreactor technology, contributing to advancements in these vital industries.

Laboratory Fermenter Manufacturer in Karnataka

Across the state of Karnataka, laboratory fermenter manufacturers are instrumental in supplying laboratory-scale fermenter equipment. These manufacturers focus on crafting reliable laboratory fermenter systems suitable for various applications, including biotechnology, pharmaceuticals, and research. Their commitment to quality ensures dependable solutions for cultivating microorganisms and cells, essential for biopharmaceutical production and scientific experimentation. Collaborating with a laboratory fermenter manufacturer in Karnataka guarantees access to cutting-edge technology, supporting progress in these industries.

Laboratory Bioreactor Manufacturer in Karnataka

In Karnataka, renowned for its industrial and scientific prowess, laboratory bioreactor manufacturers excel in precision engineering. They specialize in crafting high-quality laboratory bioreactor systems for biotechnology, pharmaceuticals, and research sectors. Their innovative solutions enable efficient cultivation of microorganisms and cells, crucial for biopharmaceutical production and scientific investigations. Collaborating with a laboratory bioreactor manufacturer in Karnataka ensures access to state-of-the-art bioreactor technology, fostering advancements in these critical industries.

Laboratory Fermenter Suppliers in Bengaluru

In Bengaluru, a city of innovation, laboratory fermenter suppliers are vital in providing laboratory-scale fermenter equipment. These suppliers offer a wide range of laboratory fermenter systems tailored to biotechnology, pharmaceuticals, and research needs. Their commitment to quality ensures dependable solutions for cultivating microorganisms and cells, essential for biopharmaceutical production and scientific experimentation. Collaborating with laboratory fermenter suppliers in Bengaluru guarantees access to cutting-edge technology, supporting advancements in these industries.

Laboratory Bioreactor Suppliers in Bengaluru

Bengaluru, a hub of innovation, hosts laboratory bioreactor suppliers dedicated to providing high-quality laboratory bioreactor systems for biotechnology, pharmaceuticals, and research sectors. Their solutions enable efficient cultivation of microorganisms and cells, crucial for biopharmaceutical production and scientific investigations. Collaborating with laboratory bioreactor suppliers in Bengaluru ensures access to state-of-the-art bioreactor technology, contributing to advancements in these critical industries.

Laboratory Fermenter Suppliers in Karnataka

Across the state of Karnataka, laboratory fermenter suppliers are instrumental in supplying laboratory-scale fermenter equipment. These suppliers offer a diverse range of laboratory fermenter solutions tailored to biotechnology, pharmaceuticals, and research. Their commitment to quality ensures reliable solutions for cultivating microorganisms and cells, essential for biopharmaceutical production and scientific experimentation. Collaborating with laboratory fermenter suppliers in Karnataka guarantees access to advanced technology, supporting the growth and innovation of these industries.

Laboratory Bioreactor Suppliers in Karnataka

In Karnataka, renowned for its industrial and scientific achievements, laboratory bioreactor suppliers excel in providing high-quality laboratory bioreactor systems for biotechnology, pharmaceuticals, and research sectors. Their solutions enable efficient cultivation of microorganisms and cells, crucial for biopharmaceutical production and scientific investigations. Collaborating with laboratory bioreactor suppliers in Karnataka ensures access to state-of-the-art bioreactor technology, fostering advancements in these critical industries.

Pilot Scale Fermenter Manufacturer in Bengaluru

Pilot Scale Fermenter Manufacturer in Bengaluru

In the tech-savvy city of Bengaluru, pilot-scale fermenter manufacturers lead the way in producing specialized equipment for scaled-up fermentation processes. These manufacturers are experts in crafting robust pilot-scale fermenter systems catering to diverse sectors such as biotechnology, pharmaceuticals, and research. Their precision engineering and dedication to quality ensure the efficient cultivation of microorganisms and cells, critical for biopharmaceutical production and scientific exploration. Collaborating with a pilot-scale fermenter manufacturer in Bengaluru provides access to advanced technology, contributing to the growth and innovation of these vital industries.

Pilot Scale Bioreactor Manufacturer in Bengaluru

Innovation thrives in Bengaluru, where pilot-scale bioreactor manufacturers excel in precision engineering. They specialize in designing high-quality pilot-scale bioreactor systems tailored to the needs of biotechnology, pharmaceuticals, and research sectors. Their innovative solutions enable efficient cultivation of microorganisms and cells, essential for biopharmaceutical production and scientific investigations. Collaborating with a pilot-scale bioreactor manufacturer in Bengaluru ensures access to state-of-the-art bioreactor technology, advancing critical industries.

Benchtop Fermenter Manufacturer in Karnataka

Across Karnataka, benchtop fermenter manufacturers play a pivotal role in supplying compact and efficient fermenter systems. These manufacturers focus on crafting reliable benchtop fermenters suitable for various applications, including biotechnology, pharmaceuticals, and research. Their commitment to quality ensures dependable solutions for cultivating microorganisms and cells, essential for biopharmaceutical production and scientific studies. Collaborating with a benchtop fermenter manufacturer in Karnataka guarantees access to cutting-edge technology, supporting progress in these industries.

Stainless Steel Bioreactor Manufacturer in Karnataka

In the heart of Karnataka, stainless steel bioreactor manufacturers are experts in crafting durable and hygienic bioreactor systems. These manufacturers specialize in designing high-quality stainless steel bioreactors ideal for biotechnology, pharmaceuticals, and research applications. Their solutions enable efficient cultivation of microorganisms and cells, crucial for biopharmaceutical production and scientific investigations. Collaborating with a stainless steel bioreactor manufacturer in Karnataka ensures access to state-of-the-art bioreactor technology, fostering advancements in these critical industries.

Lab Fermenter Suppliers in Bengaluru

In Bengaluru, a city of innovation, lab fermenter suppliers are vital in providing laboratory-scale fermenter equipment. These suppliers offer a wide range of lab fermenter systems tailored to biotechnology, pharmaceuticals, and research needs. Their commitment to quality ensures reliable solutions for cultivating microorganisms and cells, essential for biopharmaceutical production and scientific experimentation. Collaborating with lab fermenter suppliers in Bengaluru guarantees access to cutting-edge technology, supporting advancements in these industries.

Glass Bioreactor Suppliers in Bengaluru

Bengaluru hosts glass bioreactor suppliers dedicated to providing high-quality glass bioreactor systems for biotechnology, pharmaceuticals, and research sectors. Their solutions enable efficient cultivation of microorganisms and cells, crucial for biopharmaceutical production and scientific investigations. Collaborating with glass bioreactor suppliers in Bengaluru ensures access to state-of-the-art bioreactor technology, contributing to advancements in these critical industries.

Table Top Fermenter Suppliers in Karnataka

Across Karnataka, tabletop fermenter suppliers are instrumental in supplying compact and efficient fermenter systems suitable for smaller-scale applications. These suppliers offer a diverse range of tabletop fermenter solutions tailored to biotechnology, pharmaceuticals, and research. Their commitment to quality ensures dependable solutions for cultivating microorganisms and cells, essential for biopharmaceutical production and scientific experimentation. Collaborating with tabletop fermenter suppliers in Karnataka guarantees access to advanced technology, supporting the growth and innovation of these industries.

Automatic Bioreactor Suppliers in Karnataka

In Karnataka, renowned for its industrial and scientific achievements, automatic bioreactor suppliers excel in providing high-quality automatic bioreactor systems for biotechnology, pharmaceuticals, and research sectors. Their solutions enable efficient cultivation of microorganisms and cells, crucial for biopharmaceutical production and scientific investigations. Collaborating with automatic bioreactor suppliers in Karnataka ensures access to state-of-the-art bioreactor technology, fostering advancements in these critical industries.

Fermentation Vessel Manufacturer in Bengaluru

Here, we study cutting-edge technologies and approaches that are revolutionizing the biotechnology business. Welcome to our comprehensive guide on bioprocessing. We at Uma Pharmatech Machinery work hard to give you the most recent knowledge and understanding of bioprocessing so you can keep on top of this quickly changing industry.

What is The Price Of Fermentor and Bioreactor?

Applications of Fermentation Plants:

Fermentation plants have a wide range of applications, including:

Farms: Fermentation plants can convert animal manure and other agricultural waste into biogas and fertilizer, reducing waste sent to landfills and providing a renewable energy source.

Food processing facilities can use fermentation plants to convert food waste into biogas and fertilizer, reducing waste sent to landfills and providing a source of renewable energy.

Municipalities can use fermentation plants to convert organic waste materials like food scraps and yard waste into biogas and fertilizer, reducing waste sent to landfills and providing a renewable energy source.

Uma Pharmatech Machinery is Best Manufacturer and Exporter For Enzymes Manufacturing Plant In India.

Industrial Fermenter

Capacity is an important factor to consider when choosing a fermenter. The volume of liquid that the fermenter can hold determines it. The appropriate capacity will be determined by the amount of liquid to be fermented.

Material Of Fermenter: Fermenters are made from different materials such as stainless steel, glass, and plastic. Because of its durability, ease of cleaning, and corrosion resistance, stainless steel is the most commonly used material in the biotechnology industry.

Sterilization is a critical process in the biotechnology and pharmaceutical industries. A fermenter should be simple to sterilize and keep sterile throughout the fermentation process.

Agitation is an important part of the fermentation process. It aids in uniformly mixing the liquid contents, allowing the fermentation process to occur uniformly throughout the liquid.

Temperature control: Temperature is an important factor that affects the rate of fermentation. Throughout the fermentation process, a fermenter should be able to maintain a constant temperature.

Pressure control is required in some fermentation processes to maintain optimal conditions. The fermenter should be capable of withstanding the necessary pressure levels.

Supply of oxygen: In aerobic fermentation processes, oxygen is critical. The fermenter should be designed to supply enough oxygen to the fermentation process.

The world of fermenter manufacturing and bioreactor production is teeming with innovation and expertise. Across the globe, numerous manufacturers are dedicated to providing top-of-the-line solutions that meet the evolving needs of industries and research institutions. From industrial-scale fermenters to laboratory-grade equipment, these manufacturers are reshaping the landscape of biotechnology. Whether in India or elsewhere, the relentless pursuit of excellence, sustainability, and customer satisfaction drives these companies to push boundaries and revolutionize the field of fermenter manufacturing.

Best Bioreactor Manufacturer in Bengalore

The selection of the appropriate fermenter is Machine to the success of your fermentation process. Factors such as capacity, material, sterilization, agitation, temperature control, pressure control, and oxygen supply should be considered when selecting a fermenter. By taking these factors into account, you can choose the best fermenter in Bangalore for your specific needs, ensuring a successful fermentation process.

Pilot Scale Fermenter

It is Best to consider your specific needs when choosing a Industrial fermenter. The type of fermentation process, the volume of liquid to be fermented, and the level of automation required are all factors to consider.

A benchtop fermenter may be the best option for small-scale processes. These fermenters are simple to use and require little upkeep. They are also inexpensive, making them ideal for small-scale manufacturing.

For large-scale processes, a production-scale fermenter may be the best option. These fermenters are fully automated and designed to handle large volumes of liquid. Advanced features include in-situ sterilization, automatic pH control, and dissolved oxygen monitoring.

Laboratory Bioreactor Manufacturer in Bengaluru

Research and development are the foundations of biotech progress. Laboratory fermenters, which are specially developed for research purposes, have become essential instruments for scientists and researchers. A number of manufacturers in India specialize in providing high-quality laboratory fermenters that allow for experimentation, process optimization, and the acceleration of scientific breakthroughs. These companies cater to the needs of laboratories, ensuring precise control, scalability, and ease of use.

What is a Fermentation Tank?

Fermentation tanks are specialized vessels that are used to promote and control the biological and chemical reactions that occur during the fermentation process. The materials used to construct these tanks are resistant to the harsh chemical and biological reactions that occur during fermentation. Temperature control systems, agitation mechanisms, and carbon dioxide release valves are also unique features that aid in the fermentation process.

There are several types of fermentation tanks, each designed for specific applications. The following is a list of possible candidates:

Open Fermentation Tanks: These tanks are exposed to the elements, allowing the fermentation process to take place naturally. They’re common in the wine and beer industries.

Closed Fermentation Tanks: These tanks are completely sealed, so no outside air can enter. They are commonly used in biotech industries, where a controlled environment is necessary.

Conical Fermentation Tanks: These tanks have a cone-shaped bottom, which makes it easy to collect yeast and other sediments that accumulate during the fermentation process.

Several factors can impact fermentation tank performance, including:

Temperature: To ensure optimal fermentation, the temperature inside the tank must be kept within a certain range.

Agitation: Agitation promotes even fermentation by distributing heat and oxygen throughout the tank.

pH: To prevent the growth of harmful bacteria, the pH level inside the tank must be kept within a specific range.

Carbon Dioxide: To avoid a pressure buildup that could damage the tank, carbon dioxide produced during fermentation must be released from the tank.

Advantages of Bioreactors:

Bioreactors have several advantages over traditional production methods, including:

High Yield: Bioreactors have the ability to produce large amounts of microorganisms, enzymes, and other biopharmaceuticals.

Bioreactors can reduce production costs by using renewable resources and reducing waste.

Bioreactors provide a controlled environment for the growth of microorganisms, resulting in optimal production conditions.

Bioreactors use renewable resources and generate less waste, making them a more sustainable method of production.

Fermentation Vessel Manufacturer in Bengaluru

The fermenter and bioreactor manufacturing industries are brimming with creativity and experience. Numerous manufacturers throughout the world are committed to producing Automatic Fermenter Control solutions that match the increasing needs of industries and research institutes. These manufacturers are altering the biotechnology scene, from industrial-scale fermenters to laboratory-grade equipment. The constant pursuit of excellence, sustainability, and customer satisfaction motivates these enterprises to push limits and revolutionize the field of fermenter manufacture, whether in India or elsewhere.

What is Bioprocessing?

To create useful bioproducts, the multidisciplinary discipline of bioprocessing combines biology, engineering, and technology. It entails using live organisms, such bacteria, yeast, or mammalian cells, to make a variety of things, like medicines, enzymes, biofuels, and more.

How Important Bioprocessing Is

Bioprocessing is essential for improving healthcare, generating sustainable energy, and protecting the environment. Scientists and engineers can develop novel answers to society’s most pressing problems by harnessing the power of living things. Let’s look at the main fields where bioprocessing is effective:

1. Bioreactor For Pharmaceutical Sector

Bioprocessing is crucial to the pharmaceutical industry’s ability to produce biologics such antibodies, vaccines, and therapeutic proteins. These biologics provide specialized choices for treating problems like cancer, autoimmune diseases, and hereditary issues. These life-saving medications can be produced on a massive scale using bioprocessing techniques like fermentation and cell culture.

2. Bioreactor For Renewable energy and biofuels

The manufacturing of biofuel relies heavily on bioprocessing, which offers a sustainable substitute for fossil fuels. Enzymatic hydrolysis and microbial fermentation are two processes that effectively turn organic materials like agricultural waste, algae, or special energy crops into sustainable energy sources like bioethanol and biodiesel. These biofuels help fight climate change by lowering greenhouse gas emissions.

3. Bioreactor For Enzymes Manufacturing

Chemical reactions are accelerated by enzymes as natural catalysts. Industrial enzymes used in a variety of industries, including textiles, food & drinks, and detergents, can be produced on a large scale by bioprocessing. Because they are more efficient, specialized, and kind to the environment than conventional chemical processes, enzymes have considerable benefits over them.

The Bioprocessing Workflow

Upstream Processing: Cells or microorganisms are cultivated in the first stage and made to develop in a controlled environment. In order to achieve optimal cell development and production, this requires choosing the right growth media, adjusting the environment, and keeping an eye on important factors.

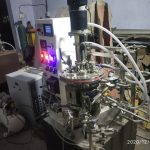

Bioreactor Operation: Following their transfer into bioreactors, the cultivated cells or microorganisms receive the nutrition and environmental conditions required to produce the desired bioproduct. Depending on the needs of the production, bioreactors can range from modest laboratory setups to enormous industrial vessels.

Downstream Processing: After the bioproduct has been created, the target compound is purified and concentrated using downstream processing procedures. To produce a high-quality finished product, a variety of separation, filtration, and purifying processes are used.

Formulation and Packaging: Following purification, the bioproduct goes through formulation and packaging procedures to guarantee stability, effectiveness, and ease of use. This action entails

Manufacturers of Bioreactor in Bengaluru-Karnataka

The use of bioreactors and fermenters has revolutionized industries like medicines, biotechnology, and food production. They are Best Equipments in contemporary industrial operations. These Advance technologies offer regulated settings for microorganism growth and metabolism, enabling effective and scalable production of worthwhile goods. Bioreactors and fermentors are positioned to play an increasingly important role in determining the future of manufacturing processes as a result of ongoing technological breakthroughs.

Remember that our team of professionals is here to help you with any unique needs or questions you may have regarding bioreactors and fermentors. To learn how these innovative systems can change your industrial processes, get in touch with us right away.

Contact US

- 61, Yamuna Industrial Park, Opp. Sardar Patel Estale, Vanch-dhamatvan Road, Dhamatvan, Ahmedabad, Gijarat, India-382435

- +91-9726923885, +91-8866137364

- [email protected]

- [email protected]

- [email protected]